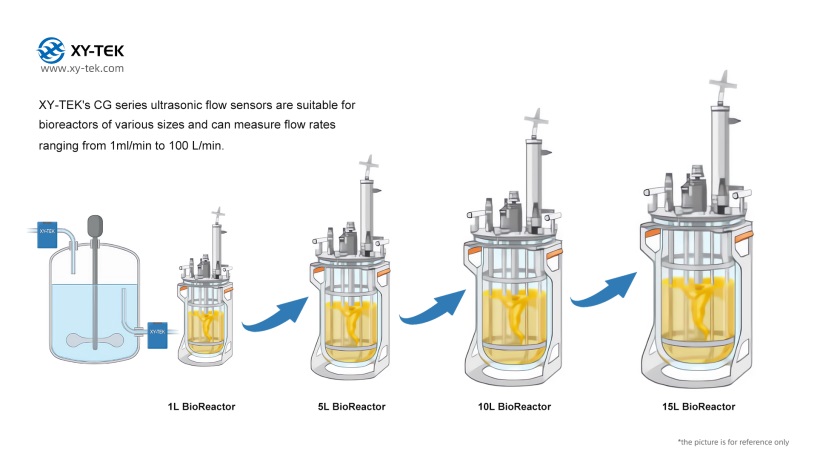

In biopharmaceutical production, efficient measurement of bio-liquids, such as nutrient media, is essential for maintaining optimal system performance.

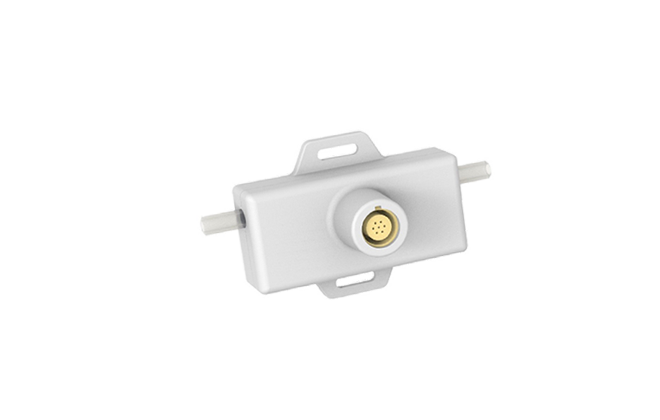

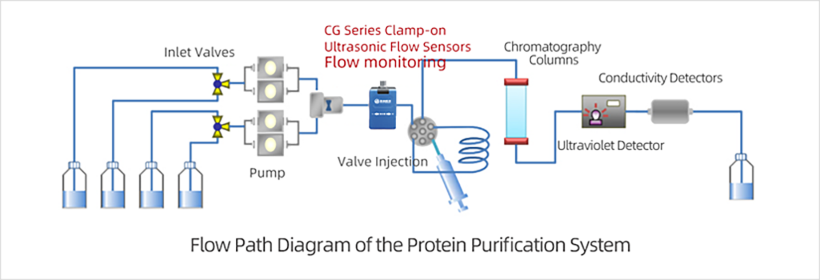

The CG series clamp-on ultrasonic flow sensors/flow meters provide the biopharmaceutical industry with a non-invasive flow rate measurement solution for verifying the performance of fluid pumps in the bioprocessing systems, monitoring pipeline integrity, and facilitating automated, intelligent bio-production management.

CG series clamp-on ultrasonic flow sensors/flow meters do not directly contact the bio flow, allowing for repeated use without costly disinfection or gamma irradiation.

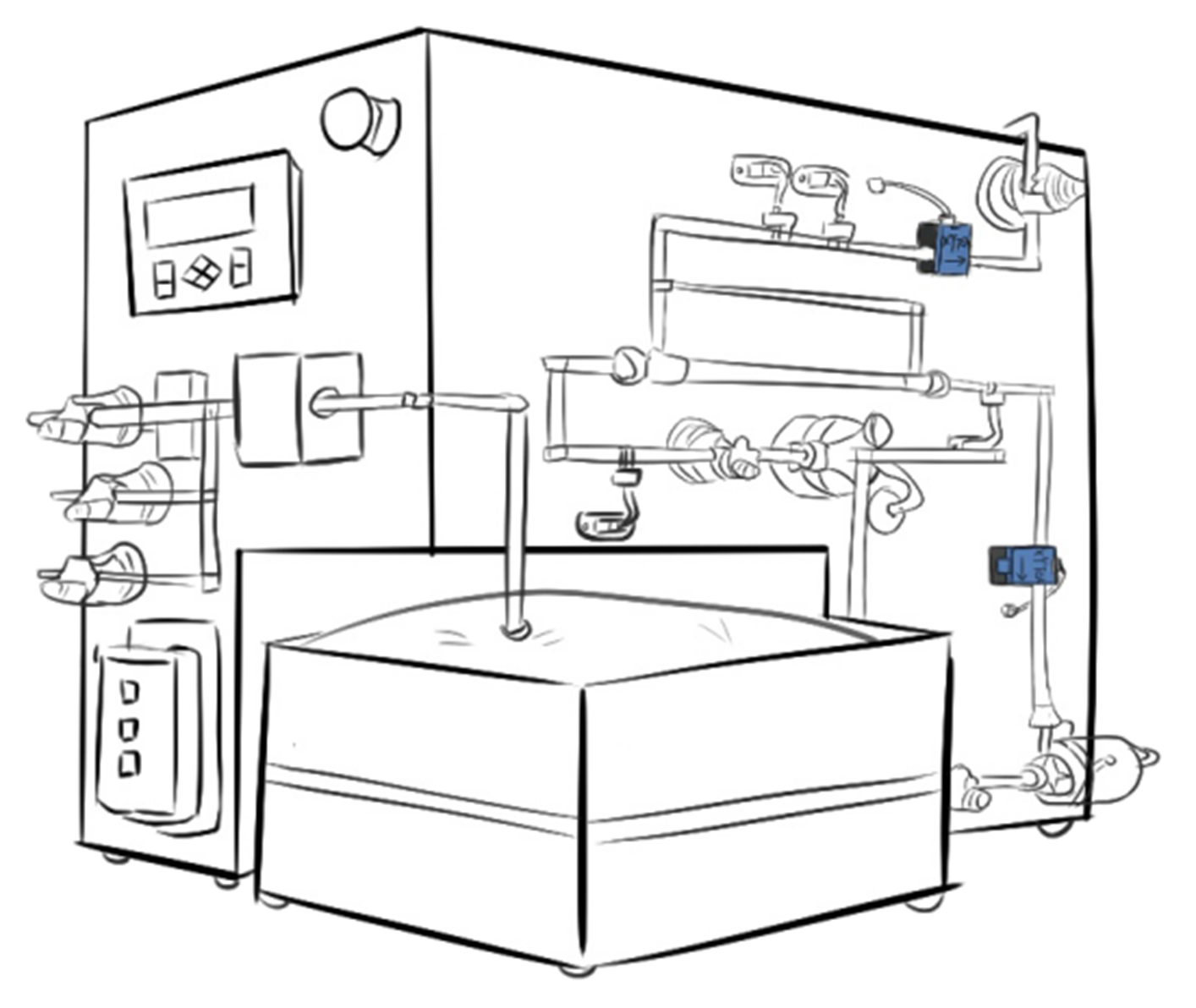

The clamp-on design makes the CG series ultrasonic flow sensors/flow meters suitable for high-sanitization environments, such as single-use biopharmaceutical systems.

Featuring a compact design, the CG series clamp-on ultrasonic flow sensors/flow meters can be easily clamped onto flexible plastic tubing, enabling accurate and reliable bio-liquid flow rate measurement without interrupting the existing setup.

Pre-Sale

Pre-Sale After-Sale

After-Sale