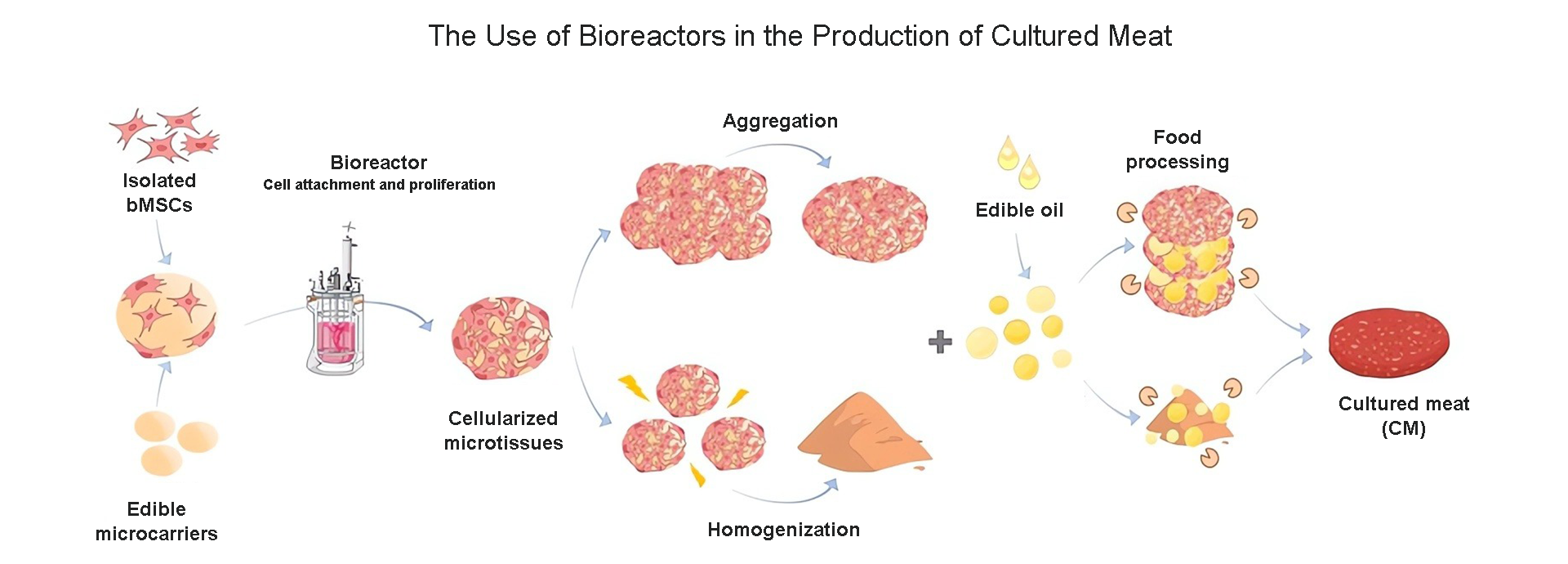

Cultivated meat, also known as cell-based meat, lab-grown meat, or cultured meat, refers to meat products that are produced by cultivating animal cells in a controlled environment rather than by raising and slaughtering animals.

This innovative approach utilizes cellular agriculture technologies, aiming at a more sustainable, ethical, and potentially healthier alternative to conventional meat production.

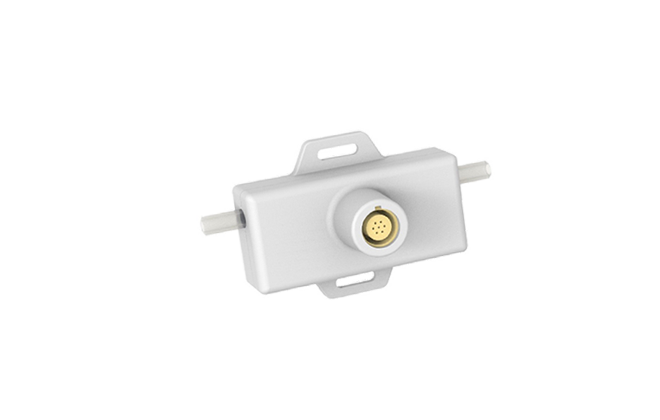

Non-invasive flow measurement is crucial in ensuring effective, sustainable, and high-quality cultivated meat production. By enabling accurate flow media measurement and monitoring, the CG series clamp-on ultrasonic flow sensor/flow meters reduces risks of flow contamination and cell damage and contributes significantly to the overall efficiency and success of the cultivated meat production bioprocessing.

Pre-Sale

Pre-Sale After-Sale

After-Sale