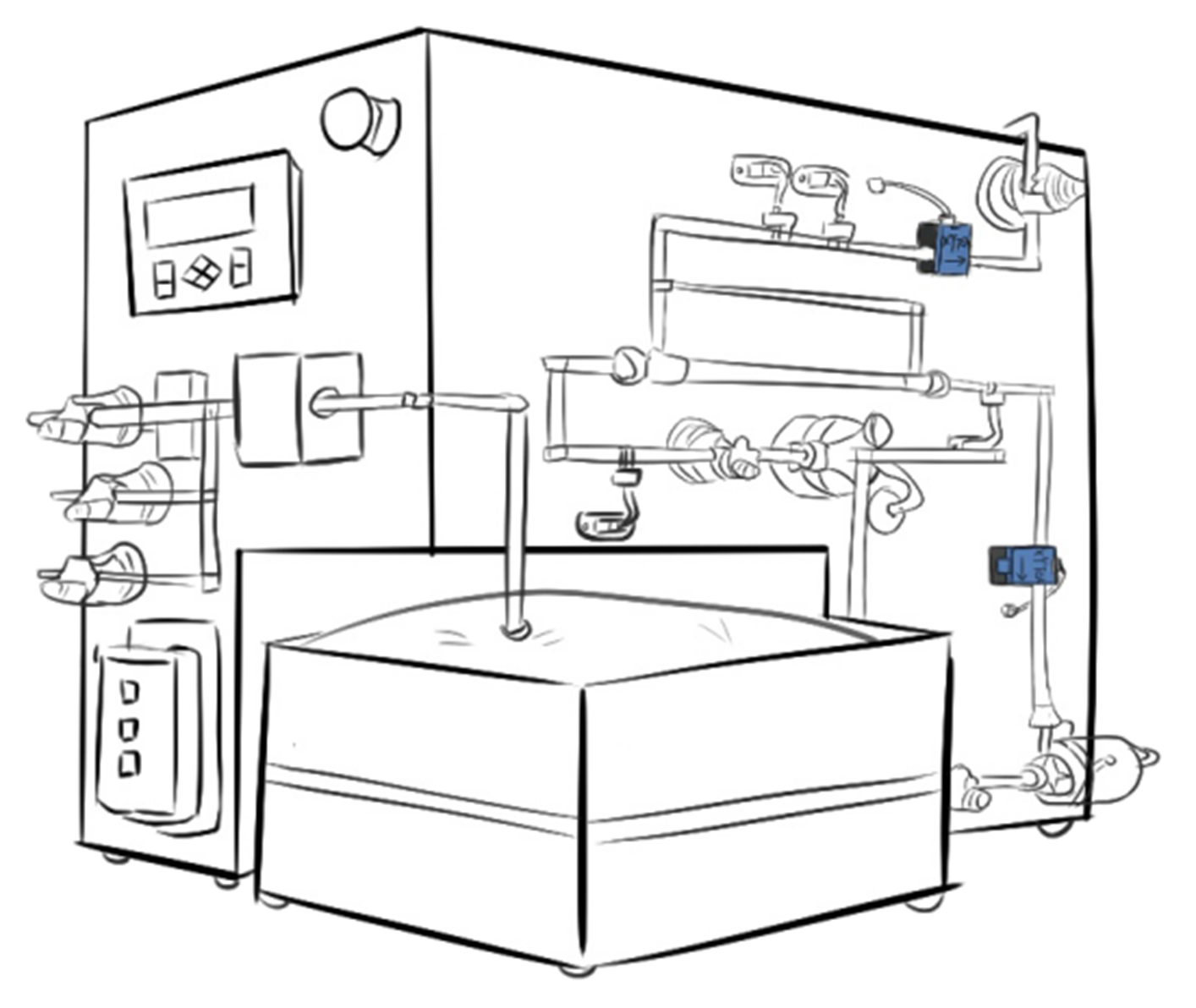

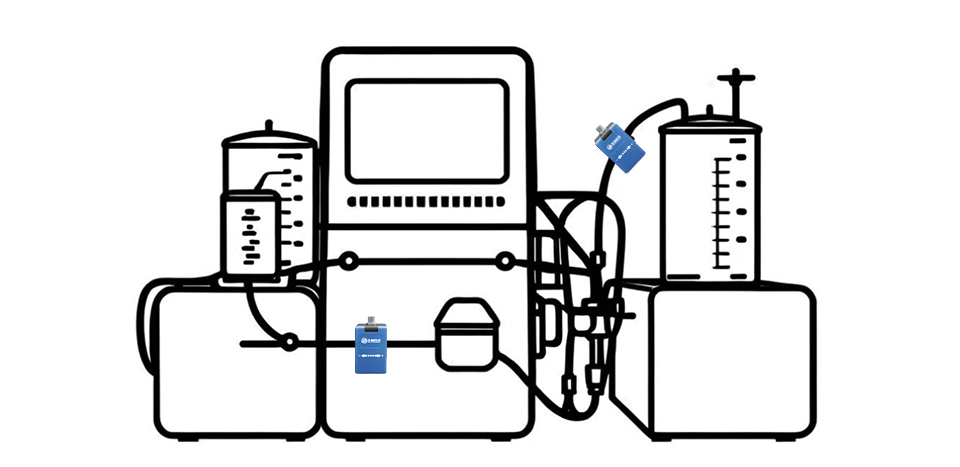

With the rapid development of the biopharmaceutical industry, the application of tangential flow filtration (TFF) in the separation and purification of biomolecules is increasing.

As a key process in a tangential flow filtration system, flow measurement directly affects the separation efficiency.

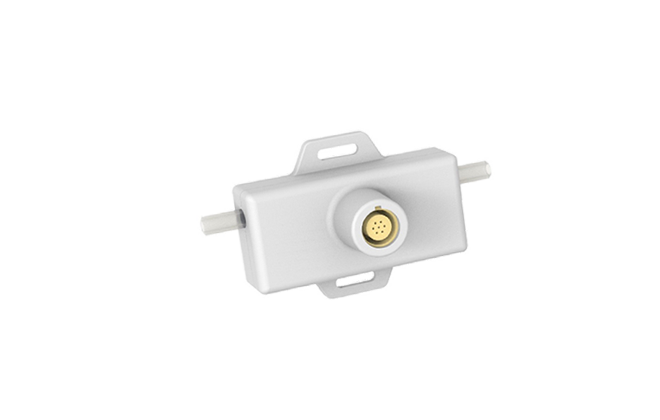

Compared with the traditional flow meters, the CG series clamp-on ultrasonic flow sensor/flow meters, has the advantages of high accuracy, good stability, no contamination, etc., which makes it ideal for TFF flow rate measurement.

Pre-Sale

Pre-Sale After-Sale

After-Sale