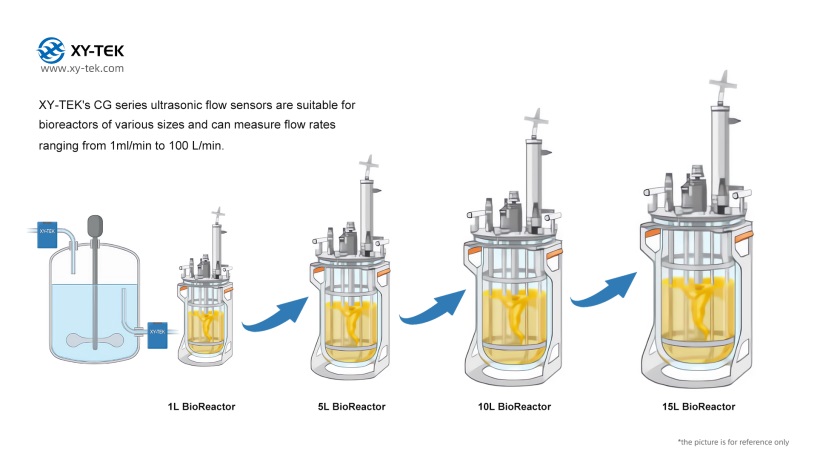

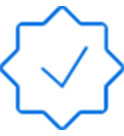

Bioreactors serve as controlled environments where biological reactions take place, playing a pivotal role in the production of pharmaceuticals, vaccines, and various bioproducts.

It utilizes microorganisms, cells, or enzymes to produce desired outcomes under optimal growth conditions such as temperature, pH, and nutrient supply. In the biopharmaceutical industry, bioreactors are essential for the controlled scaling of biological processes, ensuring consistent quality and safety in final products.

Pre-Sale

Pre-Sale After-Sale

After-Sale