Ultrasonic flow sensor / flow meter FAQ

I. Ultrasonic Flow Sensor / Flow Meter Measurable Tubing Sizes and Materials

1.What clamp-on flow sensors/flow meters does XY-TEK provide?

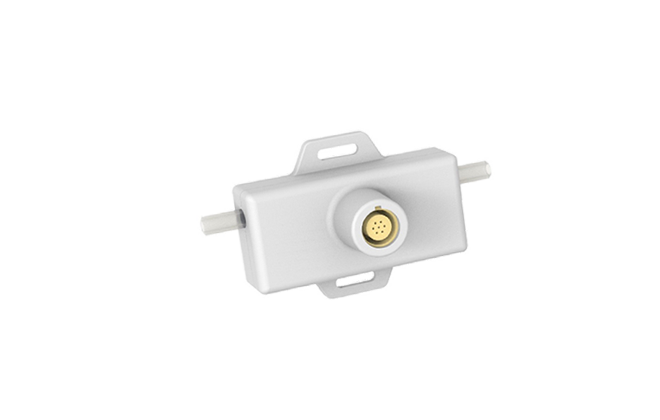

XY-TEK currently offers 4 kind of clamp-on flow sensors /flow meters series: CG, CM, CS, and CPD series. For flow sensor/flow meter product details, please visit: http://xy-tek.com

2.Which clamp-on flow sensor / flowmeters support measure flexible tubing? Which flow sensor / flow meter support measure rigid tubing?

The CG and CM series ultrasonic flow sensor / flow meters support flexible plastic tubing such as PVC. The CS and CPD series ultrasonic flow sensor / flow meters support rigid plastic tubing made of various materials, including PFA and PTFE.

3.What flexible tubing materials can the CG/CM series flow sensors / flow meters measure?

PVC tubing, silicone tubing, TPE tubing, etc. For other tubing materials, please consult XYTEK pre-sale engineers at global@xy-tek.cn

4.What are the differences between the CG and CM series flow sensor / flow meters?

The CM clamp-on flow sensor / flow meters supports RS-485 output only, supports customization, more suitable for OEM applications.

The CG series supports multiple outputs, including current, voltage, RS-485, and digital (pulse) output.

5.What tubing outer diameters (OD) are supported by CG and CM clamp on flow sensor / flow meter for flexible tubing?

CG and CM series flow sensor / flow meter supports measure flow rate in flexible tubing with OD range 4 mm–35 mm, 5/32" to 1 3/8". Other OD size can be customized. Specific OD size please visit XY-TEK website https://xy-tek.com/

6.Can CG and CM clamp on ultrasonic flow sensors / flow meters be mounted on a medical device panel?

Yes. Both CG and CM flow sensors / flow meters have reserved screw holes on the back for mounting on a medical device panel.

7.What rigid tubing materials can CS/CPD clamp on flow sensor / flow meters measure?

CS/CPD clamp on flow sensor / flow meters support measure flow rate in rigid tubing, including PFA, PTFE, Teflon, PVDF, PP, Nylon, etc. (excluding metal tubes).

8.What are the differences between CS and CPD clamp on flow sensor / flow meters?

Different mechanical design/appearance. CPD includes a display, while CS does not has display. In terms of outputs, compared with CPD, CS clamp on flow sensor / flow meters additionally supports voltage output and pulse output.

9.What rigid tubing outer diameters (OD) are supported by CS/CPD ultrasonic flow sensor / flow meters?

CS series clamp on flow sensor / flow meter currently support measure flow rate in rigid tubing with OD: 1/4" (6.4 mm), 5/16" (7.9 mm), 3/8" (9.5 mm), 1/2" (12.7 mm), 5/8" (15.9 mm), 3/4" (19.1 mm), 1" (25.4 mm). Custom OD sizes are available.

CPD series clamp on flow sensor / flow meter currently supports measure flow rate in rigid tubing with OD: 1/4" (6.4 mm), 3/8" (9.5 mm), 1/2" (12.7 mm), 3/4" (19.1 mm), 1" (25.4 mm). Custom OD sizes are available.

10.Can the clamp-on flow sensor / flow meter be installed by hanging directly on the tubing?

Yes. Installation is very flexible; the primary method is clamping directly onto the tubing.

II. Ultrasonic Flow Sensor / Flow Meter Measurable Liquid Types

1.What liquids type can XY-TEK clamp-on flow sensors / flow meter measure?

CG/CM/CS/CPD clamp on flow sensor / flow meters support measuring: water, ultrapure water, low-solids aqueous solutions, blood, milk, juice beverages, organic solvents, oils, lubricating oils, oil-based coolants, etc.

If rigid plastic tubing can withstand corrosive chemicals, CS and CPD series clamp-on flow sensor can be used for corrosive liquid measurement. Flexible tubing generally has poorer corrosion resistance, so CG and CM series flow sensor/ flow meter are typically not suitable for corrosive liquids.

2.What viscosity range can the XY-TEK clamp-on flow sensors / flow meters measure?

CG/CM/CS/CPD series clamp on flow sensor / flow meters support measuring medium-viscosity liquids < 5000 cP.

3.What viscosity range can the TGU series micro ultrasonic flow sensor / flow meter measure?

Low-viscosity liquids < 1000 cP.

4.What viscosity range can the TPD and TPK series in-line ultrasonic flow sensor / flow meter measure?

Typically < 5000 cP, for specific liquids, please contact the XY-TEK pre-sales engineers for evaluation.

5.What is the maximum measurable flow range of the XY-TEK clamp-on flow sensors / flow meters?

The flow rate measurement range depends on the specific flow sensor / flow meter model, please refer to the product catalog or the XY-TEK website. Currently, the maximum measurable flow rate range among CG/CM/CS/CPD series clamp-on flow sensor / flow meter are 0–100 L/min.

6.What is the maximum measurable flow range for the TGU series in-line flow sensor / flow meters?

For TGU series, model TGU024NS supports measurable flow rate up to 0–3000 mL/min.

7.What is the maximum measurable flow range for TPD series in-line flow sensors?

Current TPD models support up to 0.3–500 L/min.

III. Ultrasonic Flow Sensor / Flow Meter Working Temperature

1.What is the XY-TEK flow sensor / flow meter working environment temperature range?

All series flow sensor / flow meter working environment temperature : 0–60 °C.

2.What liquid temperature can XY-TEK clamp-on flow sensor / flowmeters measure?

CG/CM ultrasonic flow sensor / flow meter : 0–60 °C.

CS/CPD ultrasonic flow sensor / flow meter: 0–90 °C.

3.What liquid temperature can TGU micro flow sensor / flow meter measure?

0–100 °C.

4.What liquid temperature can TPD/TPK in-line ultrasonic flow sensor / flow meter measure?

0–90 °C.

5.What is the storage temperature of XY-TEK ultrasonic flow sensor?

All series flow sensor / flow meter: −20–70 °C.

IV. Ultrasonic Flow Sensor / Flow Meter Power Supply

1.Does the XY-TEK flow sensor / flow meter use AC power supply or DC power supply?

Except for the TH series ultrasonic flow sensor / flow meter uses 110VAC-230VAC AC operating voltage, all other series flow sensors / flow meters use DC voltage for power supply.

The DC operating voltages for each series of flow sensors are,

CG: 12–30 VDC

CS: 12–30 VDC

CPD: 12–30 VDC

TGU: 12–30 VDC

TPD: 12–30 VDC

CM: 5–30 VDC

BG bubble detector: 5–30 VDC

V. Ultrasonic Flow Sensor / Flow Meter Bubbles Detection

1.What is the detectable bubble and particle size range for the flow sensor? What is the indication method? What happens if bubbles or particles are too large?

Within a certain flow range, bubbles with a size equal to or greater than 30% of the tubing inner diameter(ID) can be stably detected. Bubbles can be visually read through the XY-TEK Flowviewer software or via switch alarm output. If bubbles are too large, they will affect flow rate measurement accuracy and repeatability.

2.What is the minimum bubble size that the XY-TEK flow sensor and bubble detector can detect?

The minimum detectable bubble size is 30% of the tubing inner diameter(ID).

3.How does the XY-TEK flow sensor/flow meters indicate bubble detection events?

Bubble detection events can be visually read through the XY-TEK Flowviewer software, or by querying the corresponding address via RS485 communication to check bubble detection status. If the flow sensors / flow meters are equipped with switch outputs, they can obtain bubble detection results by configuring the switch output.

4.How much do bubbles in the liquid will affect measurement accuracy? For example, how will the ultrasonic flow sensor / flow meter react if liquid flow is interrupted by bubbles?

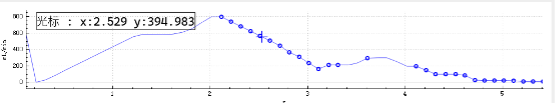

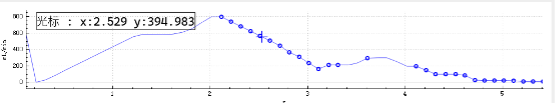

When there are numerous and continuous bubbles in the tubing, the flow sensor flow meter reading will return to 0, and the presence of bubbles will be indicated by circles in the Flowviewer observation interface. By setting the bubble damping time, short-term occasional bubbles passing through the flow sensor can be ignored; only bubbles lasting longer than the stetted value will trigger a bubble alarm.

VI. Ultrasonic Flow Sensor / Flow Meter Output and System Integration

1.What output methods does XY-TEK flow sensor / flow meter support?

XY-TEK flow sensors / flow meters support multiple output methods, such as RS485, analog output (current, voltage output), digital (pulse) output, etc.

CG/CS/TGU series flow sensors / flow meters support current, voltage, RS485, and digital (pulse) output.

CPD series flow sensors / flow meter support current, pulse, and RS485 output.

CM series flow sensors / flow meter only support RS485 output.

2.Can all series of XY-TEK flow sensor / flow meters be integrated with data acquisition modules (such as Arduino / Programmable Logic Controller PLC)?

The XY-TEK flow sensor / flow meters support integration with acquisition cards or PLCs, are compatible with Arduino, and can integrate with standard RS485 Modbus protocol devices.

3.Are all series XY-TEK flow sensors / flow meter compatible with specific brands of infusion pumps, or do the flow sensor/flow meters have general pump adaptability?

The XY-TEK flow sensor / flow meters have general pump adaptability. Currently, customers use the XY-TEK flow sensor / flow meters with peristaltic pumps, syringe pumps, diaphragm pumps, etc., and all work normally.

4.Can the TGU series in-line flow sensor / flow meters easily integrate with standard laboratory tubing and provide interface options to connect to third-party platforms for data logging?

The standard TGU-NS series product comes with NPT 1/8" connectors, which can adapt to different sizes of NPT-barb adapters, allowing connection to plastic tubing with an inner diameter of 0.8mm or larger. It is also compatible with quick-connect fittings for rigid tubing. For special requirements, the flow sensor / flow meter connectors support customization.

The TGU series flow sensor / flow meter provides RS485 output, which can be connected to a computer via a data converter, and data can be read and recorded using host computer software. The data logging format is standard CSV files, which are supported by mainstream data analysis software.

VII. Ultrasonic Flow Sensor / Flow Meter Measurement Accuracy and Performance

1.What is the reading accuracy (RD) of XY-TEK flow sensors / flow meters?

CG series and CM series clamp-on flow sensors / flow meters can achieve ±3% reading accuracy.

CS series and CPD series clamp-on flow sensors / flow meters can achieve ±2% reading accuracy.

TPD series in-line flow sensors / flow meters can achieve ±2% reading accuracy.

TGU series micro flow sensors / flow meters can achieve ±1% reading accuracy.

2.What is the repeatability accuracy of XY-TEK flow sensor / flow meters?

CS series, CPD series, TPD series, and TGU series flow sensors can achieve ±0.1% repeatability accuracy (Full Scale).

3.How does medium temperature variation affect the flow rate measurement accuracy of CG, CM, and CPD series clamp-on flow sensors / flow meters?

Medium temperature variation affects the measurement accuracy of flow sensors, and the specific impact depends on the situation.

When the medium temperature differs from the liquid temperature used during the flow sensor's factory calibration by within ±3°C, it does not affect the sensor's accuracy.

However, if the temperature change exceeds ±3°C, there will be some accuracy deviation, and the extent of deviation depends on the magnitude of the temperature change. The accuracy deviation can be compensated by adjusting the K-factor.

4.How does medium temperature variation affect the accuracy of the TGU series flow sensors?

The accuracy of TGU flow sensors/flow meter is not affected by medium temperature variations.

5. What is the impact of medium temperature changes on the accuracy of TPD/TPK in-line flow sensors / flow meters?

Temperature changes will affect the TPD/TPK in-line flow sensors / flow meters measurement accuracy. The degree of impact must be evaluated through testing based on the magnitude of the temperature change.

6. Is the measurement accuracy of an ultrasonic flow sensor / flow meter only valid if zero calibration (Set calibration point 0) is performed at the same medium temperature as the measurement?

Ideally, performing zero calibration at the customer’s measurement site—under the actual operating environment and medium temperature—achieves the highest measurement accuracy.

7. When should zero calibration (Set calibration point 0) be performed?

At the customer’s measurement site, after installing the flow sensor / flow meter into the system flow path and fixing its position, fill the tubing with liquid and make sure no air bubbles in the tubing. When the liquid is stationary (no flow), if the sensor output is not fluctuating around zero and the deviation is large, perform zero calibration to improve measurement accuracy.

8. During the service life of XY-TEK ultrasonic flow sensors / flow meters (with constant ambient temperature, humidity, and pressure), does the specified measurement error remain constant, or does it fluctuate randomly within the specified limits during operation?

Under ideal conditions (constant temperature, humidity, and pressure), the flow sensor measurement error may still exhibit small random fluctuations, mainly due to sensor zero drift. For clamp-on flow sensors / flow meters, the zero point may drift after reinstallation, but repeatability will not be affected.

9. When using a peristaltic pump, pulsating flow is generated. Will the XY-TEK flow sensor /flowmeter accuracy be affected? If so, to what extent?

Yes. Using a peristaltic pump can affect flow measurement accuracy. The extent depends on the pump’s pulsation intensity, the flow sensor / flowmeter type and performance, and whether the system includes any damping/buffering measures.

10. When using a peristaltic pump, how does the CM-series flow sensor / flow meter handle pulsating flow? Can it fully reflect pulsation?

The CM series flow sensor / flow meter can capture pulsating flow and track it in real time (instantaneous tracking).

11. Can XY-TEK calibrate the flow sensor / flow meter based on tubing samples provided by the customer?

Yes. Customers can send tubing samples to XY-TEK for application-specific calibration. This service is typically offered to OEM customers with larger purchase volumes.

12. Can CG and CM series flow sensors / flow meters be calibrated for different tubing, or must they be used with specific tubing only?

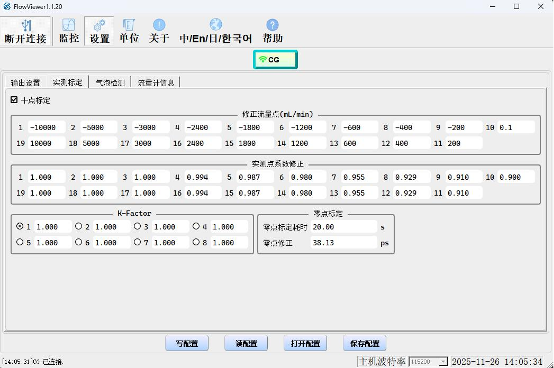

CG and CM series flow sensors / flow meters can be calibrated for different tubing. Customers can perform on-site calibration using XY-TEK PC software flowviewer.

CG and CM series flow sensors / flow meters support measuring flow rate in PVC, silicone, TPE, and other flexible tubing, and calibration parameters can be matched and optimized according to tubing characteristics.

13. When the customer changes the measured liquid, is recalibration required every time?

If the new liquid’s key physical properties (e.g., viscosity, density, gas content, acoustic properties) differ significantly from water, recalibration is generally required to achieve higher accuracy.

If the focus is on repeatability rather than absolute accuracy, recalibration is not necessary.

In most cases, customers can complete calibration themselves using the PC software Flowviewer without requiring XY-TEK tech support engineers to visit on-site each time.

If customers cannot do the recalibration, XY-TEK can provide after-sales support.

14. Does the CM series flow sensor / flow meter have fault detection? How is a fault indicated?

The CM series flow sensor / flow meter includes a software safety mechanism that performs periodic self-checks to diagnose faults without affecting flow rate measurement.

If a CM flow sensor / flow meter fails or cannot operate normally, the flow output will automatically return to zero.

15. What are the response time, delay time, and update rate of the CS series ultrasonic flow sensor / flow meter output?

The fastest response time of the CM series is 5 ms. The CM clamp on flow sensor / flow meter can also output filtered and stable results. In that case, the flow sensor / flow meter response time will be delayed accordingly (with multiple options from 1 to 60 seconds).

16. Can XY-TEK flow sensors / flow meters detect real-time flow changes instantaneously?

Yes. XY-TEK ultrasonic flow sensors / flowmeters can detect rapid changes in flow within milliseconds and output instantaneous flow measurements.

17. Do XY-TEK ultrasonic flow sensor / flow meter output an “average” flow value?

The XY-TEK ultrasonic flow sensor / flow meter can output instantaneous values, and can also output averaged (more stable) flow values.

18. Do all XY-TEK ultrasonic flow sensor / flow meter sensors support bidirectional flow rate measurement?

Yes. All XY-TEK ultrasonic flow sensor / flow meter support bidirectional flow rate measurement.

VIII. Common Questions for XY-TEK Ultrasonic Flow Sensors / Flow Meters

1. Why does the flow displayed in Flowviewer fluctuate around 0 when the liquid is stationary, instead of staying at 0?

Even when the liquid is completely stationary, the flow sensor may still output a small flow signal, which can be regarded as a noise disturbance and is also called zero drift. The fluctuation range depends on the flow sensor / flow meter model .For more details, please refer to the low-flow error range in the XY-TEK product manual.

2. How can zero calibration be configured?

CG/CM/CS/CPD/TPD/TGU series flow sensors / flow meters can all perform zero calibration via XY-TEK PC software, Flowviewer.

CG/CS/CPD/TPD/TGU series flow sensors can perform zero calibration via digital input (DI).

CPD/TGD series flow sensors / flow meters support zero calibration via the display keypad.

Please refer to the CPD Display Operation Manual and TGD Display Operation Manual for details.

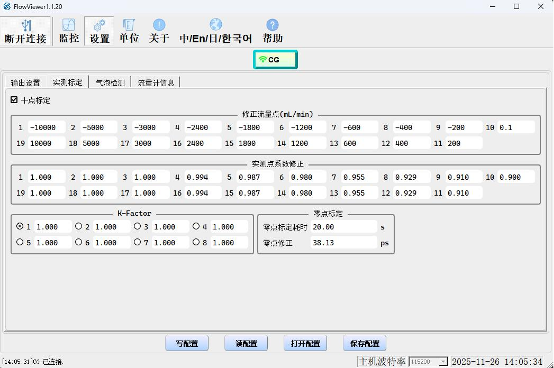

3. What do the flow points shown in the customer tool, the segment (piecewise) correction coefficients, and the eight different correction coefficients below represent?

XYTEK flow sensors / flow meters allow setting correction coefficients for 18 flow points.

In the Flowviewer software “Corrected flow points (mL/min)” table, enter the flow points to be calibrated.

In the “Measured-point coefficient correction” table, enter the corresponding correction coefficients.

Typically, the first row (No. 1–9) corresponds to flow points in the negative direction, ordered by decreasing absolute value, along with their correction coefficients.

The second row (No. 18–10) corresponds to flow points in the positive direction, also ordered by decreasing absolute value, along with their segment (piecewise) correction coefficients.

If the measured instantaneous flow falls between two flow points, the correction coefficient is obtained by interpolation using the coefficients of those two flow points.

Segment correction coefficients are usually set to 1 by default; as the absolute flow decreases, the correction coefficient gradually decreases, but typically not below 0.7.

In the “K-Factor” table, the eight values represent eight K-Factor sets. Each K-Factor can be used for an overall adjustment of the measurement results. When there are different combinations of tubing type/liquid type/liquid temperature in an application, you can calibrate one combination, determine and assign its corresponding K-Factor, and then directly call that K-Factor the next time the same combination occurs—without recalibration. For example:

Combination 1: 1/4" OD, 1/8" ID silicone tubing, 23 °C, water → calibrated K-Factor = 1; set K-Factor #1 = 1.

Combination 2: 1/4" OD, 1/8" ID silicone tubing, 37 °C, 0.9% saline → calibrated K-Factor = 1.1; set K-Factor #2 = 1.1 for convenient reuse.

4. How to connect the power supply and signal readout cables to the flow sensor / flow meter?

Connect the power positive and negative leads according to the corresponding product manual, and then connect the signal lines as needed.

5. How to view flow rate data in real time?

Users can view the real time flow rate in 3 ways:

1) The CG/TGU/CS/CM series flow sensor have no display and can connect an external XY-TEK flow sensor monitor for flow rate data reading. The CPD series flow sensor / flow meter has a built-in display and can be viewed directly on the main screen.

2) Connect the flow sensor / flow meter to XY-TEK USB converter, then connect it to a computer and view the flow data / flow volume using XY-TEK Flowviewer PC software.

3) Connect the flow sensor / flow meter to a data acquisition card (DAQ) or PLC for viewing.

6. How to obtain the XY-TEK “Flowviewer” software?

Users can register on the XY-TEK official website https://www.xy-tek.cn/ to download the software and use instructions. Sales engineers will also send the software to customers who have purchased flow sensor products and assist with installation and use.

IX. Ultrasonic Flow Sensor / Flow Meter Certification and Compliance

1. Do CG and CM series flow sensors have medical-related certifications?

CG and CM series flow sensors are measurement components, not medical devices, so they do not require standalone medical certifications. The CG and CM series flow sensors / flow meters are typically integrated into the customer’s medical device for certification.

2. Does XY-TEK hold relevant certifications such as ISO 9001, ISO 13485, CE marking, or FDA approval?

ISO 9001 has been certified. CE certification is included in the application plan. FDA is a U.S. medical certification; the CG and CM series do not apply for FDA certification on their own and are generally certified together with the customer’s medical device.

3. Are the CG and CM series flow sensor / flow meters suitable for hospital/operating-room environments, and can they withstand common wipe disinfectants?

The CM series flow sensors are suitable for hospital/OR environments. Its surface is anodized and can withstand wiping with alcohol and similar disinfectants.

The CG series flow sensors are generally recommended for laboratory environments only.

4. Is the CM series flow sensors designed according to IEC 60601 and ISO 13485?

The CM series complies with the IEC 60601 medical safety standard.

5. Does the CM series flow sensors / flow meters internal software comply with IEC 62304 Class B (or Class C)?

In the initial design, the CM series flow sensors was not developed to IEC 62304 Class B or Class C. However, CM series sensors are now widely used in medical equipment. Future versions will be developed in accordance with IEC 62304 B/C.

6. If pursuing medical-use certification for an OEM sensor, what is the approximate cost for EMC and medical safety certification?

The EMC and medical safety certification will depend on the chosen certification institution. A formal quotation can be provided if needed.

7. If pursuing medical-use certification for an OEM sensor, which safety standards must the medical OEM flow sensor follow?

XY-TEK can provide sample medical safety certification documents from existing customers for reference.

8. If pursuing medical-use certification for an OEM sensor, what is the estimated timeline?

It depends on the specific case and requires case-by-case analysis.

X. XY-TEK Ultrasonic Flow Sensor / Flow Meter Documentation and Support

1. Does XY-TEK provide calibration certificates for flow sensors?

Yes.

2. What type of calibration certificate is provided: manufacturer certificate/factory calibration report or third-party laboratory certificate?

By default, XY-TEK provides a factory calibration certificate (free of charge).

Third-party laboratory certificates are available upon request (additional cost).

3. Can XY-TEK provide documents such as datasheets, risk analysis reports, user manuals, etc. for local evaluation?

Yes.

4. Can XY-TEK provide 3D models or drawings of the flow sensor / flow meters?

They can be provided depending on the evaluation.

5. Does XY-TEK provide integration support for developers who want to integrate the flow sensor / flow meters into their own systems?

Yes—both online and on-site support are available.

XI. Ultrasonic Flow Sensor / Flow Meter Distribution and Partnerships

1. Does XY-TEK sell flow sensors / flow meter / bubble detectors outside China (e.g., Europe, Southeast Asia)?

Yes.

2. Does XY-TEK open to develop new distributors and strategic partnership relationships?

Yes.

3. Does XY-TEK offer private label or OEM customization services?

Yes, subject to certain prerequisites. Please contact the sales team at global@xy-tek.cn for details.

4. What support does XY-TEK provide to distributor partners, such as marketing materials, technical training, and after-sales service?

Marketing material support, regular product training, regular technical training, and technical support for registered customers, etc.

5. What is the global sales performance?

XY-TEK flow sensor/flow meter products have been sold to 30+ countries and regions worldwide. Sales revenue information is not publicly disclosed.

XII. Ultrasonic Flow Sensor / Flow Meter Order Delivery and Logistics

1. Is there a minimum order quantity flow sensors / flowmeters / bubble detectors (MOQ)?

No MOQ.

2. What is the production lead time for orders?

Typically 4–6 weeks.

3. What is the delivery lead time of the XY-TEK flow sensor / flow meters?

In stock: shipped within 10 business days

Out of stock: lead time approx. 4–6 weeks

4. What are the prepayment terms?

Full payment in advance; shipment after payment is received.

XIII. Ultrasonic Flow Sensor / Flow Meter Factory Visit, After-Sales Service, etc.

1. Are all the flow sensor / flowmeters manufactured by XY-TEK?

Yes. All flow sensor / flow meter / bubble detector products are independently developed and manufactured by XY-TEK.

2. Can customers visit the XY-TEK manufacturing factory?

Yes, but an appointment with the sales team must be scheduled and confirmed in advance, and a confirmation email/message must be obtained.

3. After-sales service: warranty period, RMA process, and availability of technical support

Flow sensor / flow meter products come with a 1-year warranty (consumables excluded).

Within the warranty period, issues caused by product quality will be repaired or replaced free of charge. After the warranty period, repair will be charged depending on the situation.

All products are inspected and accepted in accordance with the XY-TEK shipment standards. If the customer has any objections, please raise them within 5 days of receiving the products.

XY-TEK provides comprehensive technical support and RMA return/exchange/repair service.

Pre-Sale

Pre-Sale After-Sale

After-Sale