Ultrasonic Ablation Devices

Ultrasonic ablation is a minimally invasive procedure that uses high-frequency sound waves to generate precise thermal energy.

The thermal energy is used to target and destroy unwanted tissue such as tumors or fibroids, preserving surrounding healthy tissue. The method lever the principles of ultrasound to create localized heating through cavitation and tissue disruption.

Key Component of the Ultrasonic Ablation Devices

1. Ultrasound

Produces high sound waves that create thermal and mechanical effects in.

2. Ablation Probe

A transducer or probe that emits ultrasound waves into the target tissue.

3. Imaging Guidance

Imaging techniques, such as ultrasound or MRI, may be utilized to visualize the treatment area and guide the of the ablation probe

4. Cooling System

It is used for protecting surrounding healthy tissues from heat damage during the ablation procedure.

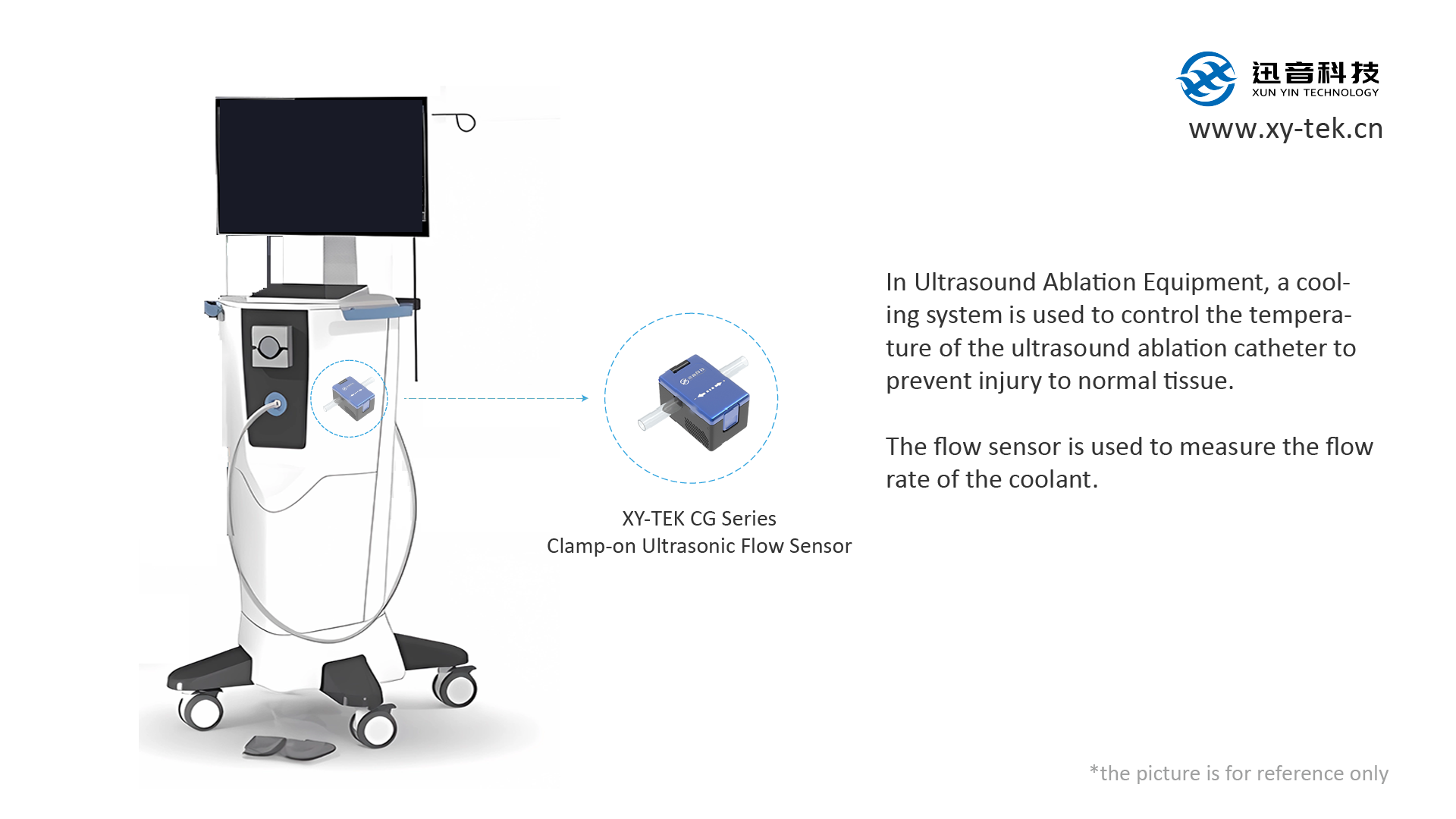

Application Scenario

In the ultrasonic ablation system, it is common to cool the areas outside the ablation probe to prevent the Ablation Catheter Probe (typically used for heating tissues or targeting areas) from overheating the non-target tissues during the process.

Combining CG series ultrasonic flow sensors / flow meters with the cooling system in ultrasonic ablation devices has enabled accurate cooling liquid flow rate measurement, contributing to real-time temperature monitoring and accurate temperature control.

The liquid cooling system help ensure that the ablation probe temperature remains within the set range during the continuous operation of the ultrasonic ablation device.

1. Monitoring Cooling Flow

By continuously measuring flow rate variations, the ultrasonic flow sensors / flow meters provide real-time data that enables the system to adjust cooling flow rates automatically.

2. Preventing Overheating in Unwanted Areas

By detecting abnormal flow alterations, the sensor prompts the control system to modify cooling flow rates or issue alerts, preventing damage to healthy tissues and ensuring patient safety.

Application Highlights

The key benefits of integrating CG series ultrasonic flow sensors / flow meters into ultrasonic ablation devices cooling system.

1. High Flow Rate Measurement Accuracy

The CG Series ultrasonic flow sensor / flow meter boasts a high flow rate measurement accuracy of ±1% and minimal error rates, helping to minimize the risk of damage to surrounding healthy tissues.

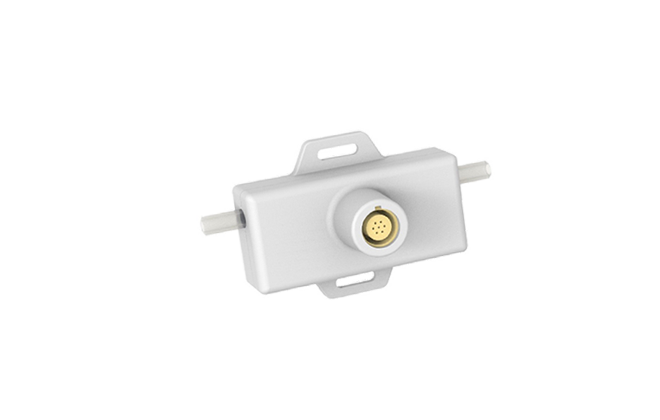

2. No-invasive Measurement, Enhanced Patient Safety

The CG series clamp-on ultrasonic flow sensor / flow meters reduces the risk of cooling liquid contamination by eliminating the need for direct contact with the fluid.

3. Measure Low Flow Rate

CG series flow sensors can measure flow rates as low as 10ml/min and detect small flow changes. This is particularly beneficial in ultrasonic ablation systems where small flow variations can have a significant impact on the patient treatment process.

4. Clamp-on Design for Seamless Integration

Designed for effortless integration into existing ultrasonic ablation devices, the CG series ultrasonic flow sensor / flow meters can help minimize downtime and operational disruptions.

5. Flow Sensor OEM

XYTEK ultrasonic flow sensor / flow meter can be tailored to meet ultrasonic ablation system-specific requirements, including alterations in sensor size, shape, color, output, tubing, and more.

For more flow sensor / flow meter information, please visit XYTEK website at https://xy-tek.com/Products/show?id=8

Contact XY-TEK team at global@xy-tek.cn

XYTEK sensor engineers would be delighted to arrange the flow sensor demonstration or provide further information to help make the flow meter selection choice.

Pre-Sale

Pre-Sale After-Sale

After-Sale