Ultrasonic Flow Sensor / Flow Meter Facts

1. What is the ultrasonic flow sensor/ flow meter?

The ultrasonic flow sensor/flow meter is a device used to measure the liquid flow rate by utilizing ultrasonic waves. It is commonly used in various applications, when properly calibrated, ultrasonic flow sensors / flow meters can measure various kind of liquids with different viscosity, density, color, and electromagnetic properties.

2. What is the clamp-on ultrasonic flow sensor / flow meter?

The clamp-on ultrasonic flow sensor is a specific type of flow sensor that can be easily attached to the outside of a tubing without the need to cut or puncture the tubing.

This non-invasive design allows quick and convenient installation and maintenance of the flow sensor, making it suitable for a wide range of hygienic applications.

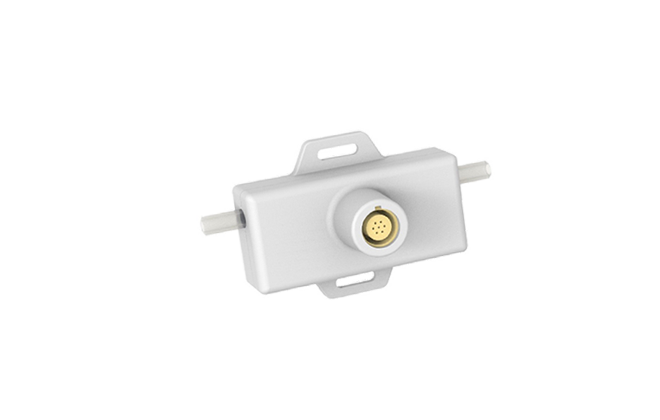

The XY-TEK CG series clamp-on ultrasonic flow sensor / flow meter supports various types of tubing materials and liquids. It can be easily installed on the outside of the tubing without any time-consuming modifications.

It is suitable for a variety of tubing materials and diameters, including VC, silicone, PFA, PE, PUR, and other materials, supports tubing OD range from 4mm to 31.8mm, ID range from 1.6mm to 25.4mm, supports precise detection of the flow rates of liquids such as water, pure water, oil, and pharmaceuticals.

Moreover, it can be easily used even in high-pressure tubing installations, reducing installation costs significantly by eliminating the need for complex construction processes.

After installation, it does not require direct contact with the fluid, avoiding potential contamination impacts and pressure losses.

It is optional to equip with an XY-TEK flow sensor monitor with a 0.96-inch display, making it easy to check the flow rate, reset the volume, and perform zero calibration.

• Installation can be completed in 10 seconds without the need to modify the tubing

• It can be attached to the outside of the tubing with a click-on design.

• The flow sensor can be installed without stopping the whole device, causing 0 disruptions

3. What is instant flow rate and cumulative flow rate?

Instant flow rate refers to the flow rate of a fluid at a specific moment in time, providing real-time information on the rate at which the fluid is flowing.

Cumulative flow rate (volume), represents the total volume of fluid that has passed through the system over a certain period, accumulated over time. Both parameters are important for monitoring and controlling fluid flow in various processes.

XY-TEK CG series ultrasonic flow sensor / flow meters support monitors the instant flow rate and cumulative volume and provides standard output options for seamless integration with customer systems, users can choose XY-TEK software Flow Viewer for intuitive data presentation.

4. What are the advantages of the XY-TEK clamp-on ultrasonic flow sensor / flow meters?

• Non-invasive and easy to install the outside of tubing without any tubing modifications.

• High flow rate measurement accuracy ±3%

• Suitable for a wide range of liquid types, such as blood, water, pure water, oil, pharmaceuticals, etc.

• Minimal maintenance requirements, with a clamp-on design

• Widely applicable in the fields of Biopharmaceuticals, medical devices, food and beverage, water treatment, thermal circulation systems, and industrial lubricants.

• Detect bubbles and large solid impurities in the liquid.

• Compatible with peristaltic pumps and other devices through international standard communication protocols. It can also be used to start/stop or control the pump speed with PID, which can be determined according to the requirements of the pump manufacturer.

5. What is the working principle of the XY-TEK ultrasonic flow sensor/flow meter?

Ultrasonic flow sensors operate based on the principle of sending ultrasonic waves through the fluid and measuring the time it takes for the waves to travel between two points in the tubing. By analyzing the differences in time, the flow rate of the fluid can be calculated accurately.

The ultrasonic transit time difference method is an advanced flow measurement technology that can be used to monitor the flow rate and cumulative volume of liquids inside the tubing. Ultrasonic flow sensors / flow meters have one or multiple pairs of ultrasonic transducers at a certain angle on both sides of the tubing. At a certain moment, the sensor circuit system uses high-frequency voltage pulses to excite the upstream transducer to generate ultrasonic waves. The ultrasonic waves pass through the tubing wall and liquid at a certain angle and are received by the downstream transducer. Subsequently, the downstream transducer emits sound waves that pass through the tubing wall and liquid in the opposite direction and are received by the upstream transducer. When the liquid flows inside the tube, there is a slight difference in the propagation time of the ultrasonic waves in the upstream and downstream directions.

This is similar to a person swimming with and against the current in a river, where the time taken to cover the same distance will differ. This time difference is directly proportional to the flow velocity of the liquid.

By precisely measuring this time difference, the sensor/flow meter circuit system can calculate the flow velocity of the liquid. By integrating the size information of the tubing, the liquid flow rate can be determined. This is the basic working principle of the ultrasonic transit-time difference technology.

6. What is the benefit of non-invasive flow rate measurement?

Non-invasive flow rate measurement eliminates the need for direct contact with the fluid being measured, reducing the risk of contamination, minimizing maintenance requirements, and ensuring the integrity of the fluid being analyzed.

XY-TEK CG series clamp-on ultrasonic flow sensor / flow meter can measure the flow rate without direct contact with the liquid, making it particularly suitable for applications with high requirements for hygiene and cleanliness and where it is not possible to install by breaking the tubing.

7. What is the difference between a clamp-on ultrasonic flow sensor and an in-line ultrasonic flow sensor/flow meter

• Clamp-on flow sensors / flow meters can be easily installed to the outside of the tubing, while in-line sensors are inserted into the tubing and in contact with the fluid.

• Clamp-on flow sensors / flow meters are non-invasive and do not disrupt the flow in the tubing, while in-line sensors may require cutting or modification of the tubing.

• Clamp-on flow sensors / flow meters are typically easier to install and remove, making them more versatile in certain applications.

8. Non-invasive ultrasonic flow sensors / flow meters for blood, perfusion liquid, bio-process liquid flow rate measurement

Non-invasive ultrasonic flow sensors / flow meters can accurately measure the flow rates of various liquids, blood in medical applications, bio-media in bioreactors, and bio-process liquids without direct contact with the fluid, reducing the risk of contamination.

9. CG series Non-invasive ultrasonic flow sensor / flow meter for low flow rate measurement

Non-invasive ultrasonic flow sensors designed for low flow rates provide accurate and reliable measurements.

When liquid flows inside the tubing, there is a slight difference in the propagation time of ultrasonic waves in the upstream and downstream directions.

The time difference is directly proportional to the flow velocity of the liquid.

The sensor circuit system can calculate the liquid flow velocity by accurately measuring this time difference, and when combined with information about the tubing dimensions, it can calculate the liquid flow rate. This is the basic working principle of the ultrasonic time difference method.

In applications where the liquid flow velocity is high, and the tube diameter is large, the corresponding time difference is also large, and can be easily calculated by the circuit system.

Therefore, there are already many mature solutions for related applications such as the transportation of petroleum, natural gas, and residential water metering. However, in cases where the tubing diameter is small and the flow velocity is low, the time difference is very small and requires extremely precise and stable hardware and software systems for resolution. This is also a significant reason why there are few companies worldwide with the capability to measure flow rates in small-diameter tubing using ultrasonic technology.

XY-TEK has been focusing on small-diameter fluid measurement for many years, overcoming relevant technological barriers and developing a range of high-performance flow sensor / flow meters to meet the challenging accurate flow rate measurement needs of global customers.

Whether it is the blood flow in the artificial heart or ECMO, or the transfer and filling of nutrient solutions and medications in disposable biopharmaceutical devices, we can provide customers with excellent flow sensor products and dedicated service support.

For more flow sensor / flow meter information, please visit XYTEK website at https://xy-tek.com

Contact XY-TEK team at global@xy-tek.cn

XYTEK engineers would be delighted to arrange the flow sensor/flow meter demonstration or provide further information to help make the flow meter selection choice.

Pre-Sale

Pre-Sale After-Sale

After-Sale