Blog

XY-TEK is a high-tech company specializing in the development, manufacturing, and sales of accurate and reliable ultrasonic flow sensors/flow meters. We specialize in flow rate measurement for small tubing and low flow rates in medical devices, bioprocessing, beverage and drink filling, industry automation, etc. XY-TEK also offers ultrasonic flow sensors, vortex flow meters, and bubble detectors OEM.

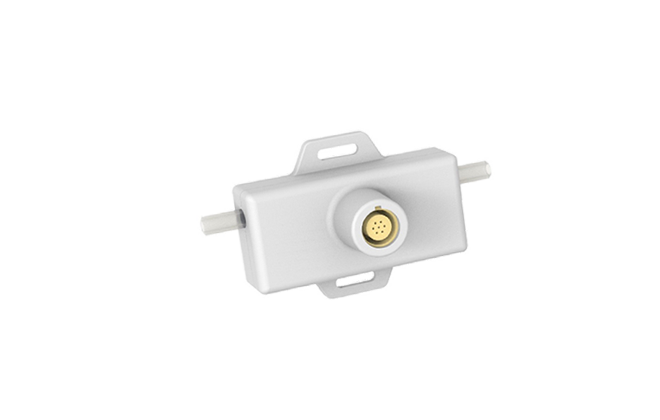

CPD Clamp-on Ultrasonic Flow Meter in Battery Electrolyte Injection Equipment

Application Background

As the global energy transition accelerates, large-scale energy storage technology has become critical infrastructure for supporting renewable energy grid integration and grid frequency/peak regulation.

Among various energy storage technological routes, Flow Batteries(especially Vanadium Redox Flow Batteries, VRFB) stand out due to their unique advantages: storage capacity is determined by electrolyte volume, while power is determined by stack size, allowing for flexible configuration.

• Long Cycle Life: Capable of over 10,000 cycles, far exceeding lithium-ion batteries.

• High Safety: The electrolyte is an aqueous solution, eliminating the risk of combustion or explosion.

• Environmentally Friendly: The electrolyte is recyclable, with no heavy metal pollution.

The Importance of Electrolyte Injection in Flow Battery Manufacturing

The electrolyte is the "blood" of a flow battery, and its accurate injection control directly impacts battery performance.

• Injection Precision Determines Cell Consistency: Deviations in injection volume within the same batch directly affect capacity consistency.

• Injection Process Affects Battery Life: Uneven injection leads to local concentration differences, accelerating capacity decay.

• Injection Efficiency Affects Production Costs: An efficient and precise injection system reduces scrap rates and improves production efficiency.

A flow battery system mainly consists of

• Two Electrolyte Tanks: Storing positive and negative electrolytes, respectively.

• Stack: Composed of multiple single cells connected in series to perform electrochemical reactions.

• Circulation Pump System: Drives the electrolyte to circulate between the tanks and the stack.

• Control System: Includes valves, pressure sensors, flow sensors, filters, etc.

The electrolyte is drawn from the tanks by circulation pumps, pumped into the stack, completes the charge/discharge reaction on both sides of the proton exchange membrane, and returns to the tanks, forming a complete external circulation system.

Industry Challenges

Challenges in Electrolyte Flow Measurement

• Insufficient Accuracy in Traditional Methods: Methods like gravity injection or pressure injection struggle to achieve high-precision flow control of ±2%.

• Impact of Physical Property Changes: Electrolyte viscosity and density change with temperature and concentration, affecting flow measurement accuracy.

• Poor Batch Consistency: Fluctuations in injection volume lead to performance differences in cells from the same batch, affecting product yield.

• Difficulty in Cooperative Control of Circulation Pumps: Positive and negative pumps providing different flow rates at the same speed lead to uneven reactant supply and aggravated concentration polarization.

• Leakage Risks: Contact-type flow meters are in direct contact with corrosive electrolytes, posing leakage hazards.

• Sensor Contamination: Active substances in the electrolyte may deposit inside the sensor, affecting measurement accuracy.

• High Maintenance Costs: Traditional flow meters require regular calibration and cleaning, resulting in a heavy maintenance workload.

• Lack of Intelligence: Lack of intelligent diagnosis and predictive maintenance functions based on flow data.

Application Introduction

The CPD Series Clamp-on Ultrasonic Flow Sensor / Flow Meter is capable of real-time flow rate measurement for various corrosive and high-purity media, offering the following core technical advantages:

• Multi-Unit Collaborative Operation: In the electrolyte preparation system, multiple CPD meters work in synergy to measure the flow of soft water and concentrated electrolyte in real-time, ensuring mixing precision.

• Real-time Injection Flow Measurement: Millisecond-level response with an LCD screen displaying real-time injection flow rates.

• Closed-Loop Control: Flow signals are fed back to the PLC to control injection pump speed and valve opening.

• Batch Statistics: Calculation of cumulative injection volume ensures consistency for every batch.

• Positive/Negative Electrolyte Circulation Monitoring: In the flow battery circulation system, CPD meters are installed on both positive and negative circulation pipes for dual-channel synchronous monitoring.

• Flow Balance Control: Adjusts circulation pump speeds based on flow differences between positive and negative poles to ensure balanced reactant supply.

• Bubble Detection: The CPD ultrasonic flow meter/flow sensor detects air bubbles in the tubing and issues real-time alerts.

• Leakage Detection: A sudden drop in flow may indicate a pipe leak.

• Blockage Warning: A gradual decrease in flow may predict filter clogging.

• Abnormal Alarm: Immediate alarms during flow anomalies prevent electrolyte concentration polarization.

• Multiple Communication Interfaces: Supports 4-20mA, RS485, Modbus RTU, and other output methods for integration with control systems.

• Flow Visualization Software: Provides dedicated "FlowViewer" monitoring software for remote flow monitoring, data logging, and report generation.

Application Highlights

• High Measurement Accuracy: Achieves ±2% accuracy and ±0.1% repeatability, which improves injection accuracy, ensures batch consistency, and reduces deviations.

• Multi-Media Adaptability: Measurement accuracy is unaffected by changes in medium viscosity.

• Energy Consumption Reduction: Optimizes injection control based on real-time flow feedback, lowering pump energy consumption.

• System Response Speed: Automated control response time shortened from seconds to milliseconds.

• Electrolyte Utilization: Precise control reduces waste of expensive electrolytes.

• Zero-Contact Design: CPD clamp flow sensors / flow meters can be clamped directly onto the outside of the tubing, completely isolated from the electrolyte.

• Corrosion-Resistant Design: Sensor housing uses corrosion-resistant materials with an IP67 protection rating, suitable for harsh industrial environments.

• Low Maintenance Design: No regular cleaning required. Even with frequent use, the calibration cycle can be set to 1-2 years, reducing labor and spare parts costs.

• No Moving Parts: No wear and tear, with a Mean Time Between Failures (MTBF) of up to 50,000 hours and a service life of 5-10 years.

• No Leakage Risk: Zero contact with the electrolyte eliminates leakage risks.

• Installation Cost Savings: Clamp-on installation reduces tubing modification expenses.

• Data Analysis: Traceable flow data allows for the optimization of injection process parameters.

• Predictive Maintenance: Predicts equipment failures based on data analysis for preemptive maintenance.

• Remote Flow Monitoring: Supports integration with industrial IoT platforms for real-time remote monitoring.

• Multi-Scenario Applicability

o Precise flow measurement for Positive/Negative electrolytes in VRFB.

o Flow rate measurement for highly corrosive media in Iron-Chromium Flow Batteries.

o Flow rate measurement for complex media in Zinc-Bromine Flow Batteries.

• Multi-Process Applicability

o Flow rate measurement for electrolyte raw material mixing ratios.

o Precise flow rate measurement for cell injection flow.

o Monitoring and optimization of electrolyte circulation flow during battery operation.

Customer Value Summary

• Improved Injection Consistency: Enhanced injection precision ensures consistent cell performance and boosts brand reputation.

• Reduced Total Cost of Ownership (TCO): Lower total usage costs across the full lifecycle of installation, operation, and maintenance.

• Operational Efficiency Uplift: Increased automation in flow measurement reduces manual intervention and labor costs.

• System Reliability: High-reliability design guarantees continuous and stable production.

• Data Foundation: Precise flow data provides the foundation for smart manufacturing.

• Automatic Control: Supports various communication outputs for integration with automated control systems.

• Future Expandability: Supports custom design, functional expansion, and upgrades.

Conclusion

Against the backdrop of rapid development in the energy storage battery industry, electrolyte injection precision and circulation control have become key factors constraining product quality and battery operating efficiency.

Verified through practical applications, the CPD Clamp-on Ultrasonic Flow Sensor / Flow Meter provides a reliable flow rate measurement solution for energy storage battery electrolyte injection equipment, thanks to its non-invasive, high-accurate, highly repeatable, and intelligent features. It not only resolves the pain points of traditional measurement methods regarding accuracy, reliability, and maintainability but also provides strong support for process optimization, quality improvement, and cost control in flow battery production through its smart capabilities.

Pre-Sale

Pre-Sale After-Sale

After-Sale