With the rapid development of the biopharmaceutical industry, biopharmaceutical companies are adopting disposable technologies from research and development, and pilot testing to large-scale production to enhance the quality of biopharmaceuticals.

The use of single-use biopharmaceutical processes can help biopharmaceutical companies reduce costs, increase efficiency, shorten the time to market for new products, effectively control product quality, reduce contamination or cross-contamination during the production process, and ensure the quality and safety of products.

Why is it important to use clamp-on ultrasonic flow sensors/flow meters in single-use biopharmaceutical processes?

XY-TEK non-contact/external-clamp ultrasonic flow sensors/flow meters are highly suitable for the biopharmaceutical process and bio-devices, especially in the single-use biopharmaceutical field, due to their appearance design, and working principles.

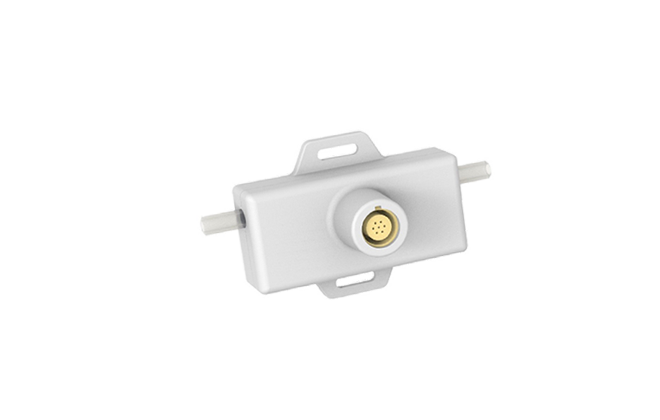

1.CG series ultrasonic flow sensors/flow meters feature an external clamp-on design, allowing easy installation or removal on disposable bioprocessing equipment tubing.

2.CG series ultrasonic flow sensors/flow meters are reusable and do not require repeated disinfection. Since the ultrasonic flow sensors/flow meters do not come into direct contact with the fluid being measured, they do not exert shear forces on cells, do not cause tubing blockages, and have no dead zones.

3.CG series ultrasonic flow sensors/flow meters offer standard analog output and digital output options, making them easy to integrate into customer systems.

XY-TEK CG series Ultrasonic Flow Sensors/Flow Meters Advantage

● High flow rate measurement accuracy and stability, with an accuracy of up to ±3%

● Support for bidirectional measurement, capable of calculating fluid volume and bubble detection

● All circuits are integrated inside the ultrasonic flow sensor/flow meter, compact in size, easy for installation

● Custom calibration is available for specified plastic tube materials, sizes, temperatures, and liquid types

● Equipped with XYTEK flow sensor monitor for convenient real-time viewing of flow data

When the flow sensor monitor is connected to the CG ultrasonic flow sensor, the two devices could function as a flowmeter for real time flow rate monitoring and management.

The CG Series clamp-on ultrasonic flow sensors / flow meter can perform various tasks to improve real-time automation and optimize bioprocess stability/performance, including but not limited to

● Detecting the tubing degradation

● Verifying the performance of the pump system

● Flow monitoring and process control/analysis

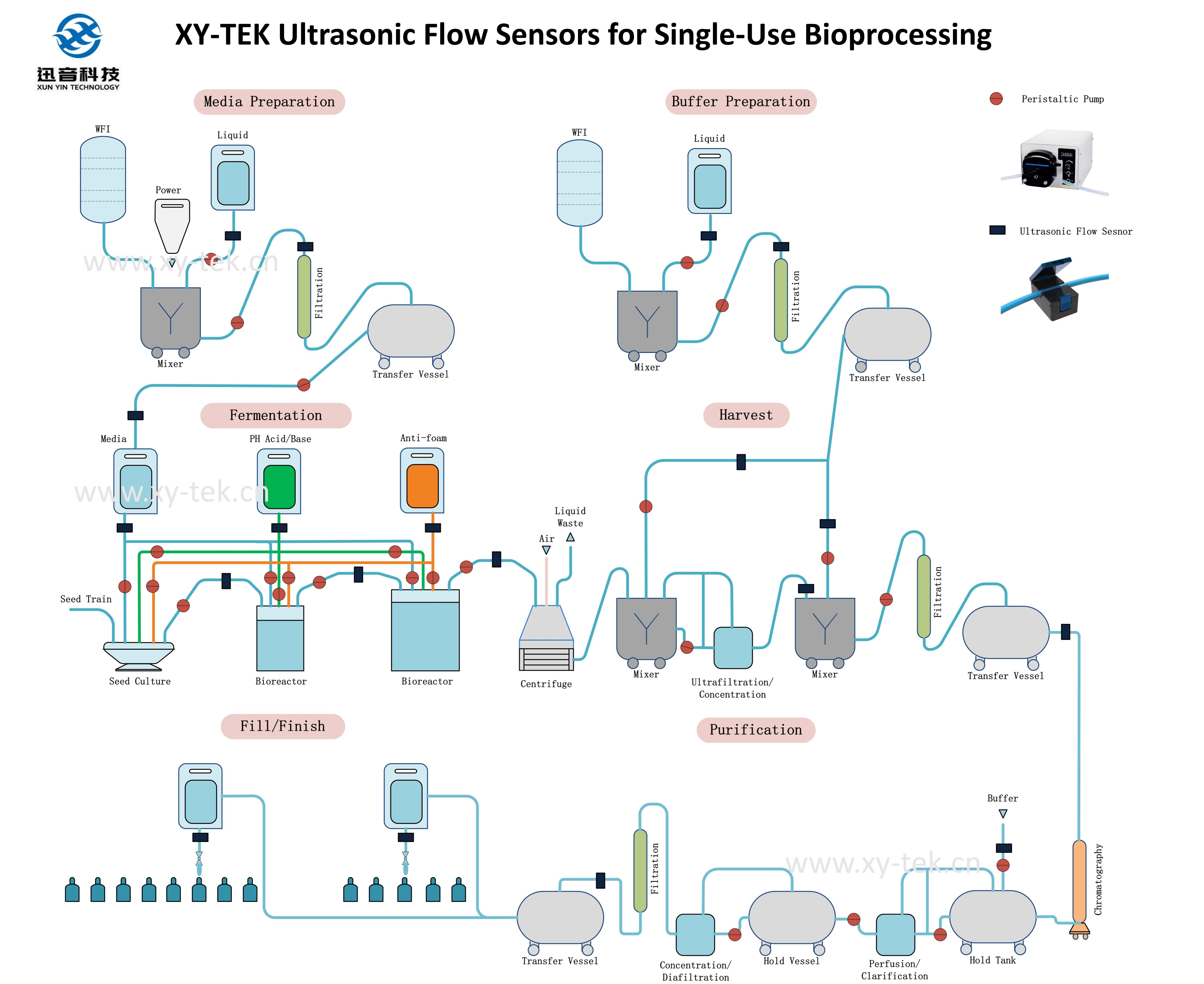

Ultrasonic Flow Sensor/Flow Meter in Single-Use Bioprocessing Systems

CG Series clamp-on ultrasonic flow sensors / flow meters can perform various tasks to enhance the real-time automation level of biopharmaceutical processes and optimize process stability and quality, such as, validating fluid pump performance, flow monitoring, and process control and analysis.

● Media/buffer prep

● Filtration

● Acid & base supply

● Inoculation

● Fermentation

● Harvest

● Chromatography

● Perfusion clarification

● Purification

● Fill/Finish

Pre-Sale

Pre-Sale After-Sale

After-Sale