Ultrasonic Flow Sensor / Flow Meter FAQ

Non-invasive Ultrasonic Flow Rate Measurement Introduction

The non-invasive ultrasonic flow sensor / flow meter utilizes ultrasonic technology to measure flow rate at critical points of various biotech processes. Ultrasonic technology enables non-invasive flow rate measurement, un-effected by liquid composition (color, viscosity, turbidity, charge, temperature, etc.).

XY-TEK ultrasonic flow sensors/flow meters can be clamped onto the outside of flexible or rigid tubing, send the ultrasonic signal through the tubing, and directly measure flow while simultaneously calculating the total volume dispensed.

The addition of real-time flow rate measurement allows for increased insight into critical process parameters (CPP) that are necessary for optimal batch-to-batch consistency and reliability. By non-invasively monitoring the process, setup time can be reduced.

In recent years, the biotech industry has shifted priorities toward maximizing process intensification by utilizing complete single-use systems. That very single-use process requires sterility at the point of delivery.

This limits the number of process analytical technology (PAT) devices that can be integrated. By adding a non-invasive flow sensor / flow meter, a single-use process can still be intensified without additional validation of materials and complexity of design.

Application of Non-invasive Flow Rate Measurement in Medical Devices

In a lot of medical devices and life support systems such as hemodialysis machines, artificial heart, organ perfusion systems, heart-lung machines, ECMO, and surgical robots, it is necessary to monitor the flow rate of blood, saline, urine, and liquid drugs to improve system safety and patients treatment efficiency.

XT-TEK non-invasive flow sensors / flow meters can measure flow rate in small tubing at low flow rates, and they are easy to install and disassemble. The flow sensors/flow meters can measure flow rate accurately and help identify potential risks in various medical operations.

For example, the flow sensors can detect failures of dialysis equipment, flow abnormals during surgery, and low blood flow and thrombosis in AVF/AVG caused by narrowing of blood vessels. They can monitor the status of pumps and the aging of tubing. These features help clinicians obtain more accurate diagnoses and avoid human operation errors on site.

In recent years, with the advancement of intelligent medical devices, the demand for non-invasive flow rate measurements is increasing quickly, not just in medical institutions, but also in daily home care and remote treatments.

How does a clamp-on ultrasonic flow sensor/flow meter work?

The ultrasonic flow sensor / flow meter utilizes the transit-time difference technology to non-invasively measure flow rates within flexible or rigid tubing. Ultrasound waves are propagated by matter and are sensitive to changes in such matter. These changes seen between the emitted ultrasound waves and received ultrasound waves are directly related to the velocity of any given liquid and allow for the calculation of the total volume.

The upstream and downstream sensors are piezoelectric crystals that transmit and receive the ultrasonic signal. The ultrasonic waves then propagate through the liquid at an angle relative to the axis of the tubing. The transit time in the upstream direction is always larger than that in the downstream direction when there is flow. The time difference in both directions is proportional to the mean flow velocity, and together with the tubing cross-section area information, the volume flow rate can be derived.

XY-TEK ultrasonic flow sensor/flow meter includes an upstream and downstream sensor element, it can measure bidirectionally.

What are the tubing requirements of a clamp-on flow sensor/flow meter?

A CG series ultrasonic flow sensor / flow meter can works with majority of the flexible tubing materials on the market. The most important aspect to consider when selecting a sensor is the Outer Diameter (OD).

For flexible tubing, sensors typically range in size from 0.25 inches up to 2 inches OD.

Another detail to consider is that the Inner Diameter (ID) must not be less than 50% of the OD. If the ID is less than 50% of the OD, the wall thickness is too large and the flow path is too small for accurate flow measurements.

Other metrics to consider when selecting an XY-TEK flow sensor or any non-contact flow sensor/flow meter – include tubing material, process temperature, fluid type, and flow rate.

What are the three types of non-invasive flow sensors / flow meters?

Typically, there are three types of non-invasive flow sensors for different tubing/flow rate applications such as:

1.Clamp-on for flexible/single-use tubing

2.Clamp-on for rigid tubing

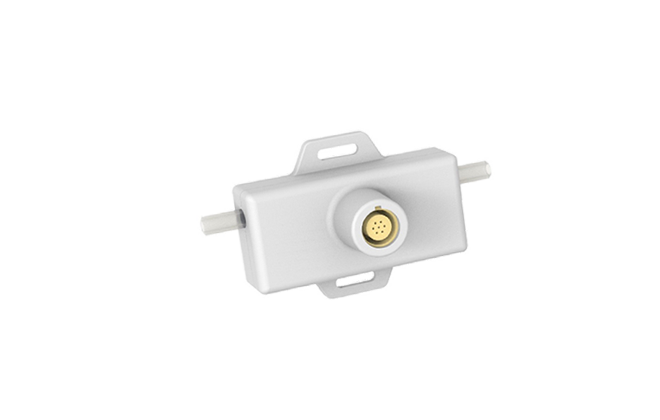

3.In-line flow sensor/flow meter for very low flow

XY-TEK ultrasonic flow sensors / flow meter come in three types:

1.CG series: For flexible tubing applications

2.CS series: For rigid tubing applications

3.TGU series: For in-line ultra-low flow applications

Depending on your process conditions, XY-TEK can help find the right sensor for you.

Please contact us (CALL +86 21 33885752 or SEND E-MAIL to global@xy-tek.cn) for a quick consultation.

How accurate are non-invasive flow sensors/flow meters?

Current non-invasive flow sensors on the market will offer on average +/-5% accuracy, based on a flow volume verification via a scale or graduated cylinder. In process and with a custom calibration to tubing type, fluid, and temperature, that accuracy can typically be improved.

XY-TEK ultrasonic flow sensors / flow meters can measure with +/-3% accuracy when the flow rate is less than 100mL/min, depending on the tubing size. Greater flow rates (>100mL/min) can consistently produce +/-3% accuracy.

The higher the flow rate, the greater the transit-time difference is measured, allowing for increased accuracy. Also, higher accuracy and repeatability can be realized with a custom calibration.

What are common applications for a clamp-on flow sensor / flow meters?

Essentially, anywhere flow is desired to be measured and controlled during a process that utilizes flexible or rigid tubing.

This includes buffer & media preparation/manufacturing, perfusion, fermentation, cell culture, fill & finish dosing, TFF & chromatography skids, peristaltic pump performance monitoring, bioreactor harvest, artificial heart operation, hemodialysis machines, organ transplantation, blood pump, and many more. The XY-TEK ultrasonic flow sensor / flow meter can be a valuable addition to process intensification and PAT initiatives.

Can ultrasonic flow sensors detect air bubble?

Yes.

When more than 50% of the tubing is filled with air, the flow sensor/flow meter will provide a steady 0mL/min signal. This output can be configured within a control strategy to present an alarm or process data point that indicates air is present within a process. This can enhance process quality control and be used as a safety measure.

Do clamp-on flow sensors / flow meters come calibrated?

Yes.

It is industry standard to provide a factory calibration for new flow sensors/flow meters. This calibration is then further strengthened once in the process by applying tubing type, fluid type, flow rate range, and process temperature to the sensor correction factors. By calibrating a clamp-on flow sensor to your specific application details, very high accuracy and repeatability can be realized.

All XY-TEK Flow sensors come factory-calibrated across their entire operational flow range. Flow Viewer software allows end users to modify this calibration as needed to provide additional accuracy.

With the support of XY-TEK after-sale engineering team, the ultrasonic flow sensor / flow meter can be calibrated to users application details. Up to 8 calibration factors can be saved and readily accessed to provide a wide range of accuracy for changing processes. These calibrations are saved directly to the sensor's internal memory, allowing for plug-and-play functionality.

How is a clamp-on flow sensor / flow meter installed?

Most non-invasive ultrasonic flow sensors / flow meters are simply clamped down on the desired tubing and accessed via the manufacturer's software, or they are externally powered and integrated for data collection.

At the beginning of each process, the tubing is primed and a 20-second zero-point calibration is performed. From there, the flow sensor is ready to begin collecting instantaneous flow rate and total volume.

How can the XY-TEK ultrasonic flow sensor / flow meter be integrated into existing control systems?

The XY-TEK flow sensor has several digital and analog outputs to choose from, such as:

• 0-20mA

• 4-20mA

• 0-5V

• 0-10V

• RS485, with Modbus and CRC protocols readily available

The Flow Viewer software allows for the customization of digital output modes, including flow switch, air detection, volume dosing, and pulse output. These digital outputs can be inverted, NPN, PNP, or Push-Pull. The XY-TEK ultrasonic flow sensor / flow meter can also start-stop or PID control a pump, depending on the pump manufacturer.

For more flow sensor/flow meter information, please visit XYTEK website at https://xy-tek.com

Contact XY-TEK team at global@xy-tek.cn

XYTEK engineers would be delighted to arrange the flow sensor/flow meter demonstration or provide further information to help make the flow meter selection choice.

Pre-Sale

Pre-Sale After-Sale

After-Sale