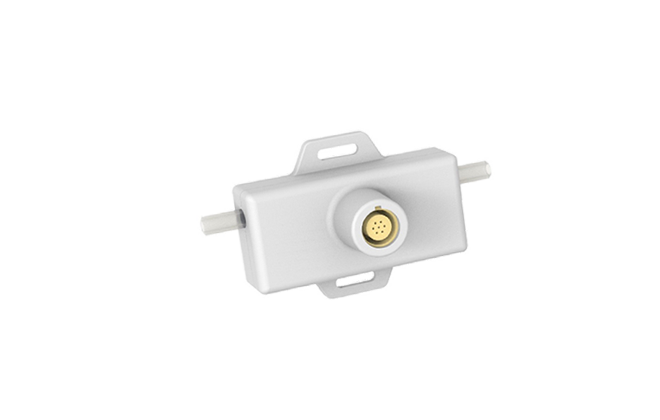

The BG series ultrasonic bubble detectors/bubble sensors are used to detect air bubbles in the fluid-filled plastic tubing accurately. It can identify gas and liquid states at specific locations.

The BG series ultrasonic bubble detectors offer customizable response time, allowing it to be tailored to meet the unique requirements of various applications, including medical devices, bioprocessing, industrial automation, food and beverage dosing, spraying, and lubrication.

Applications

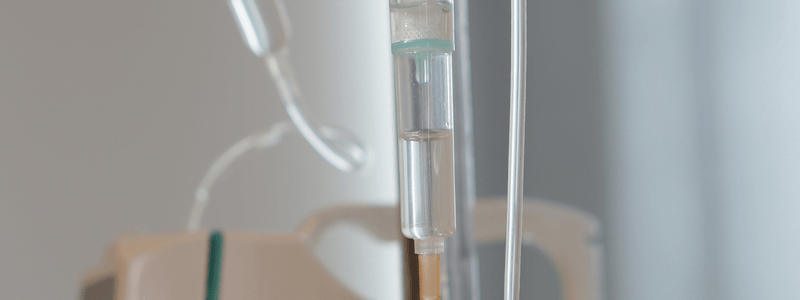

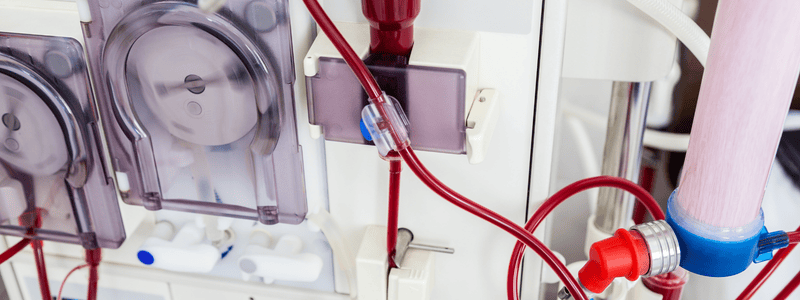

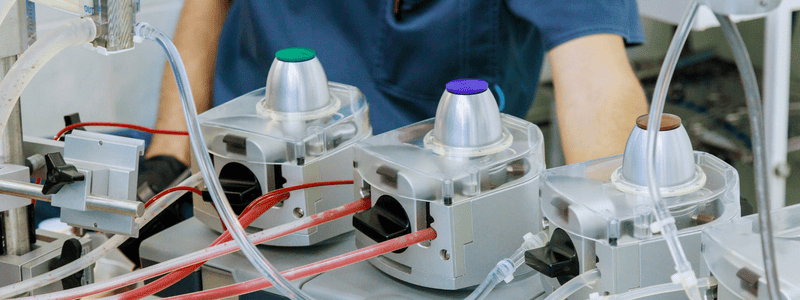

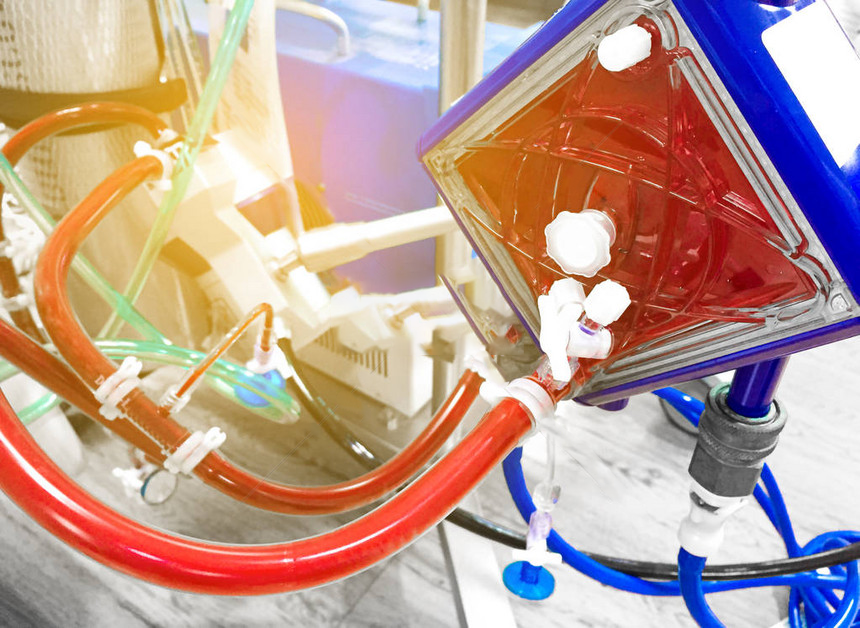

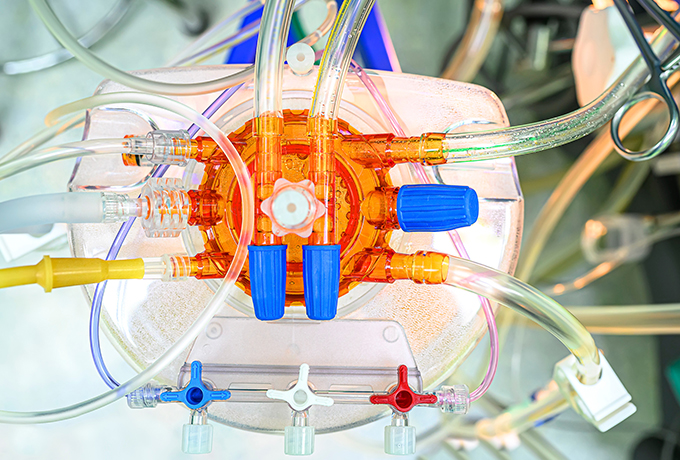

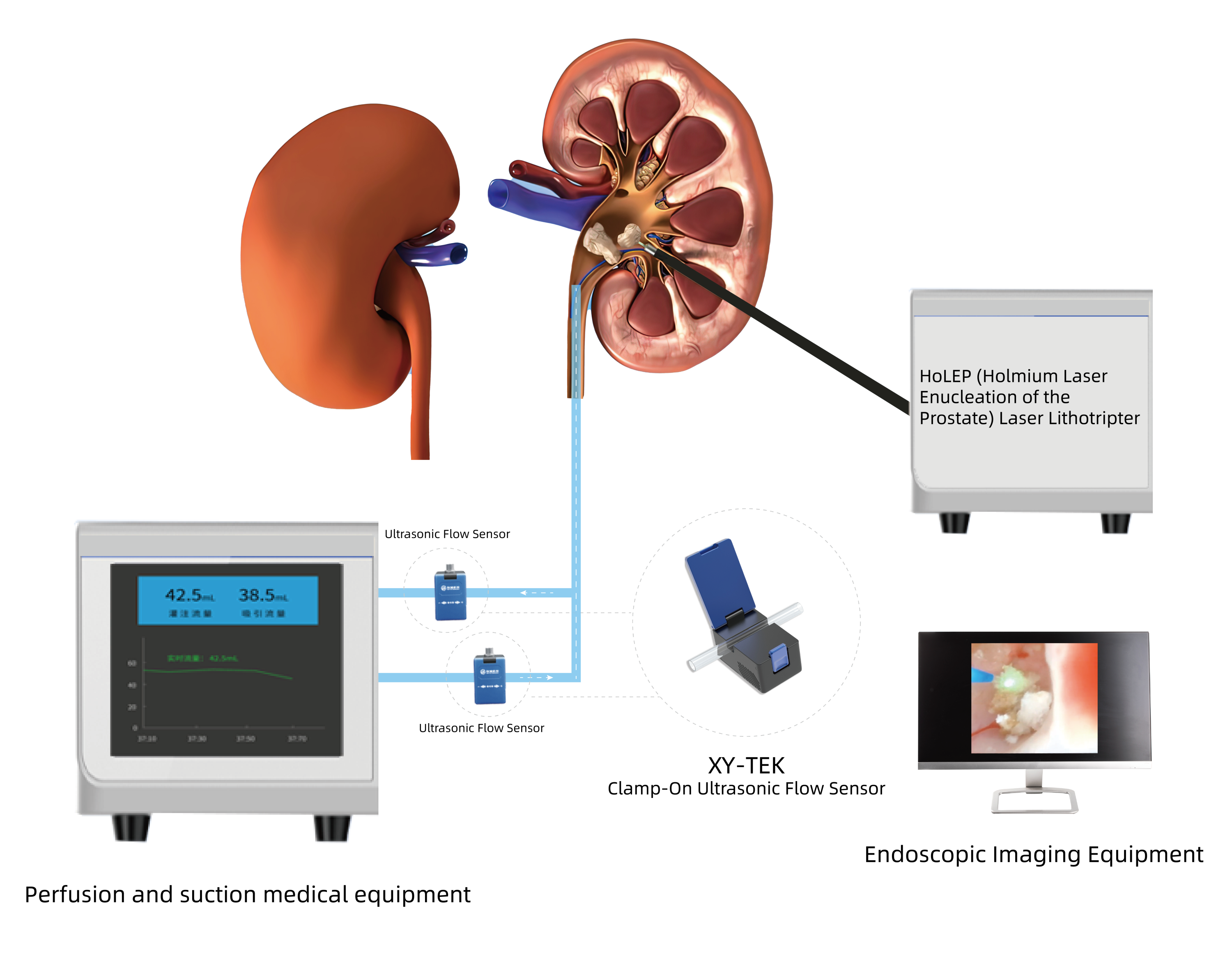

• Medical devices such as the hemodialysis machine, organ transplantation system, the heart-lung machine, the blood pump, and microwave ablation devices.

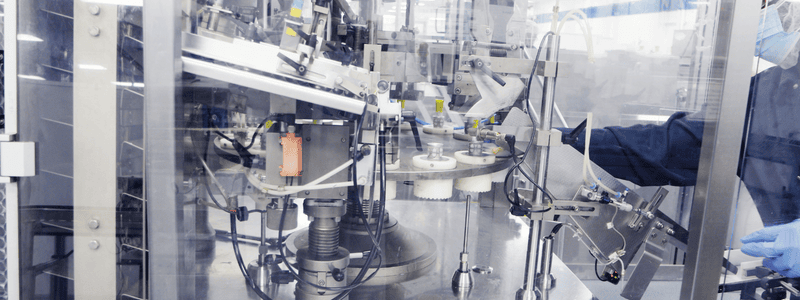

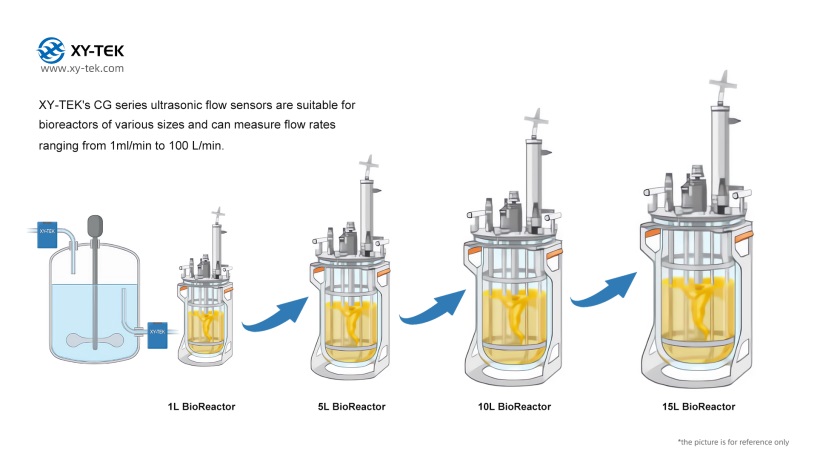

• Biopharmaceutical processes and equipment, such as single-use systems, fermenters, cell culture equipment, vaccine production, tangential flow filtration systems, and liquid chromatograph devices.

Pre-Sale

Pre-Sale After-Sale

After-Sale