CPD Clamp-on Ultrasonic Flow Meter for Wet Cleaning Equipment

CPD Clamp-on Ultrasonic Flow Meter for Wet Cleaning Equipment

Application Background

In the process of electronics manufacturing, cleaning is a crucial step. Almost every procedure (such as after etching or cutting) requires the thorough removal of surface silicon dust, organic matter, metal ions, and impurities to ensure device performance and the stability of subsequent processes.

Currently, wet cleaning technology is evolving towards greater efficiency, intelligence, and environmental friendliness. Cleaning equipment typically employs tank or spray systems, combined with ultrasonic technology, acidic/alkaline reagents (such as Potassium Hydroxide, Hydrogen Peroxide), and rinsing processes to achieve high-efficiency cleaning at specific temperatures. Typical workflows include pre-cleaning, chemical cleaning, rinsing, and drying.

The cleaning process affects not only product quality but also involves high operational costs—chemical consumption is huge, purity inevitably drops during use, and waste liquid treatment poses a heavy environmental burden. Traditional production lines still rely on manual chemical liquid addition, where the amount and timing are difficult to control precisely. This leads to fluctuations in chemical concentration, unstable cleaning results, and potential safety hazards.

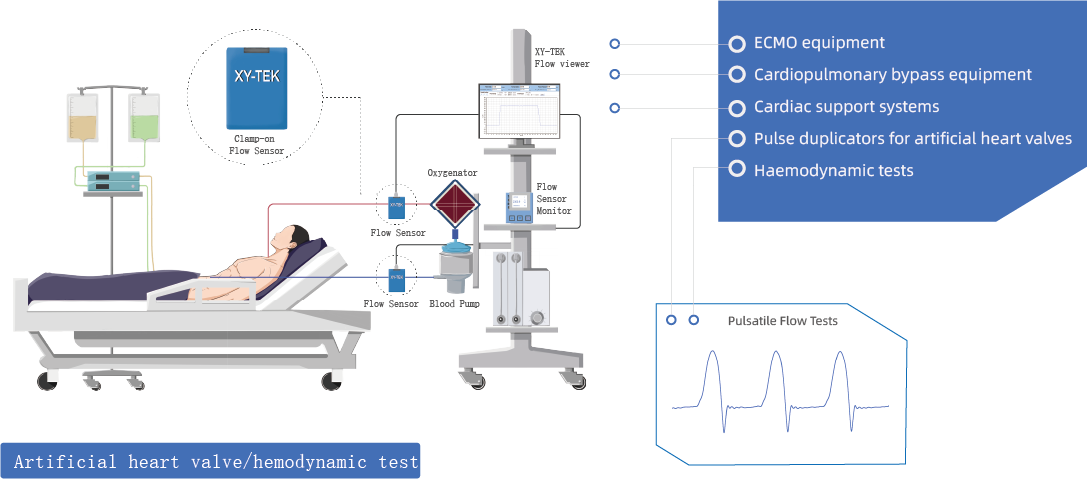

In this context, an automated, precise chemical circulation flow measurement system has become the ideal choice for upgrading cleaning equipment. The flow rate measurement and control module must monitor key parameters of the chemicals in real-time and automatically control replenishment and drainage based on preset logic. This ensures stable chemical quality while maximizing utilization and reducing waste and emissions. As the "sensory nerve" of this intelligent control system, the ultrasonic flow meter’s accuracy, reliability, and repeatability directly influence the quality and stability of the cleaning process.

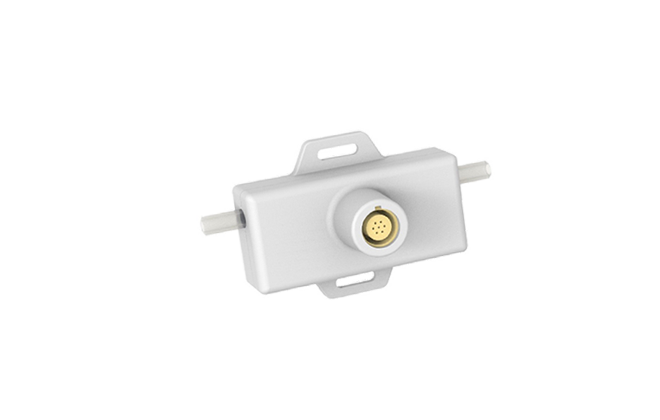

The CPD Clamp-on Ultrasonic Flow Sensor / Flow Meter is designed for the chemical circulation and water supply systems of wet cleaning equipment. It provides non-invasive flow rate measurement and supports real-time feedback and automatic control. Featuring a corrosion-resistant housing and a compact size, the CPD ultrasonic flow sensor / flow meter is compatible with various types of cleaning equipment.

Industry Challenges

Flow rate measurement in wet cleaning equipment faces multiple challenges stemming from process characteristics, medium properties, and special production environment requirements.

1. Insufficient Chemical Flow Rate Measurement Accuracy: The addition of cleaning chemicals (e.g., strong acids, alkalis, oxidizers) requires precise, segmented control. In automatic dosing systems, chemical addition often needs to be accurate to the ml level. Detecting such minute flows places extremely high demands on the flow sensor sensitivity, resolution, and stability.

Ordinary flow meters often have flow rate measurement bias in the low-flow range, failing to meet the needs for precise ratio mixing and cost control. Errors in chemical flow measurement lead to concentration fluctuations and uneven cleaning, causing residual impurities on the wafer surface and lowering product yield.

2. Corrosion and Contamination Risks: Chemicals used in cleaning, such as Hydrofluoric Acid (HF), Nitric Acid, Potassium Hydroxide (KOH), and Hydrogen Peroxide, are highly corrosive. Metal parts or ordinary plastics in traditional flow meters are prone to corrosion, aging, or even dissolution after long-term contact. This not only causes flow rate measurement inaccuracy but may also introduce metal ion contamination into the cleaning fluid, seriously affecting wafer purity. This material compatibility issue forces many equipment manufacturers to frequently replace flow meters, increasing maintenance costs and downtime.

3. Bubble Interference: Cleaning chemicals may contain specific concentrations of particles or generate micro-bubbles during use. These impurities and bubbles can interfere with the operation of mechanical flow meters, leading to increased errors in flow measurement results.

4. Resource Consumption and Complex Tubing: The cleaning process consumes a vast amount of water (e.g., rinsing tanks need continuous replenishment), and the piping layout is complex. Without real-time flow feedback, it is impossible to optimize the recycling of cleaning water, leading to increased wastewater discharge and energy waste.

5. Maintenance and Calibration: Cleaning production lines requires equipment to run 24/7. Flow meters must withstand acidic atmosphere environments and require minimal maintenance. Traditional flow meters often need regular maintenance, increasing the risk of downtime.

6. Installation Constraints in Compact Spaces: Cleaning equipment strives for high space utilization, resulting in compact piping layouts with very limited space for flow meter installation. Traditional flow meters require long straight pipe sections for installation, and their bulky size can interfere with the layout and maintenance of other components.

7. Collaborative Management of Multi-Chemical Systems: Cleaning equipment needs to handle multiple chemicals simultaneously—acidic cleaners, oxidizers, rinse water, etc. Since each medium has different characteristics, the flow meters in the equipment must be able to accurately measure flow across various media to reduce equipment complexity and cost.

CPD Clamp on Flow Sensor Application Introduction

Addressing the flow rate measurement needs of wet cleaning equipment, CPD Clamp-on Ultrasonic Flow Sensor / Flow Meters are able to provide accurate, repeatable flow rate measurement results without contacting any cleaning media, providing accurate flow data for intelligent automation control systems.

1. Chemical Circulation and Precise Replenishment: In chemical delivery and circulation systems, the flow meter is integrated into the dosing line to measure the flow rate of chemicals added to the cleaning tank in real-time. The CPD offers a measurement resolution of up to 0.1 mL. Real-time flow data is fed back to the PLC. Through preset logic (e.g., adding 20 mL of KOH per 10,000 wafers), the PLC adjusts the pump frequency or control valve opening, forming a closed-loop control circuit. This achieves dynamic dosing, maintaining chemical concentration within the optimal process window and ensuring stability.

2. Rinse Water Supply Monitoring: Installed at the rinse tank outlet and supply branches, the meter monitors the flow of ultrapure water or rinsing fluid. By precisely metering inflow and outflow, the cleaning system can intelligently judge the rinsing effect and water quality changes. This minimizes water consumption and wastewater discharge while guaranteeing cleaning quality, realizing significant water-saving and cost-reduction benefits.

3. Safety and Auxiliary Monitoring: CPD clamp-on flow sensors / flow meters are deployed in heating, circulation, or filtration tubing. Preset thresholds trigger automatic alarms upon flow anomalies. The CPD flow meter includes a built-in air bubble detection function capable of identifying micro-bubbles (diameter ≥ 1/3 of pipe ID) in real-time, supporting traceability of flow rate and volume data.

4. Corrosion-Free and 0 Contamination: The CPD clamp-on flow sensor /flow meter utilizes a corrosion-resistant housing and can be clamped directly onto the outer wall of the cleaning fluid tubing. Ultrasonic signals penetrate the tubing wall for measurement, keeping the flow sensor completely isolated from strong acids and alkalis. This design offers a triple advantage:

1. The flow rate measurement channel is immune to corrosion, offering a longer lifespan than contact meters.

2. It eliminates the risk of the flow meter contaminating the chemical liquid, ensuring cleaning purity.

3. Maintenance does not require draining the tubing; the CPD flow sensor / flow meter can be removed directly, greatly simplifying the process.

5. Adaptability and Intelligence for Complex Media: The advanced ultrasonic signal processing algorithms used in the CPD flow sensor / flow meter effectively identify and compensate for interference caused by micro-bubbles and solid particles in the fluid. It outputs stable and reliable flow data for all types of cleaning media.

6. System Integration and Automation: The CPD flow meter provides convenient interfaces and rich functionality. It supports mainstream industrial communication protocols (such as Modbus, Profibus) for easy integration into the cleaning equipment's PLC or central control system. Measurement data is not only used for real-time control but can also be recorded, stored, and uploaded to the MES (Manufacturing Execution System). This enables traceability of chemical consumption per batch of Silicon Carbide cleaning, cost accounting, and process optimization, providing key data support for refined management and smart manufacturing.

Application Highlights

The application of the CPD Clamp-on Ultrasonic Flow Sensor / Flow Meter in wet cleaning equipment creates value in process improvement, cost savings, and automation controls.

1. Enhanced Cleaning Stability and Efficiency: High repeatability (±0.1% FS) and millisecond-level response ensure precise chemical replenishment, reducing concentration fluctuations. This improves the consistency of cleaning results, reduces wafer breakage rates and residual impurities, and helps improve cell conversion efficiency by over 15%.

2. Cost Savings and Environmental Optimization: The non-contact design maximizes chemical utilization rates and reduces waste liquid discharge. It simplifies tubing and lowers maintenance costs. The maintenance-free structure reduces downtime, supporting the shift from manual operation to automatic control.

3. Corrosion Resistance and Safety Assurance: The housing is made of acid and alkali-resistant materials, making it suitable for complex operating environments.

4. Excellent Engineering Applicability: The CPD flow sensor / flow meter is compact, requires no tubing cutting, and has very low requirements for straight tubing sections. It perfectly adapts to the tight and complex piping layouts inside cleaning equipment, facilitating equipment design and maintenance.

5. Intelligent Upgrade: Multi-media adaptability and IoT integration support flow data traceability and predictive maintenance. This significantly enhances cleaning quality and consistency, driving the intelligent upgrade of equipment to meet advanced process requirements.

Conclusion

The accurate flow data provided by the CPD Clamp-on Ultrasonic Flow Sensor / Flow Meter makes predictive maintenance, self-optimization of process parameters, and lean analysis of energy and material consumption possible.

It helps cleaning equipment manufacturers build smarter, more transparent, and more efficient cleaning processes, achieving better cost control capabilities and more stable product quality to gain a lasting competitive advantage.

Pre-Sale

Pre-Sale After-Sale

After-Sale