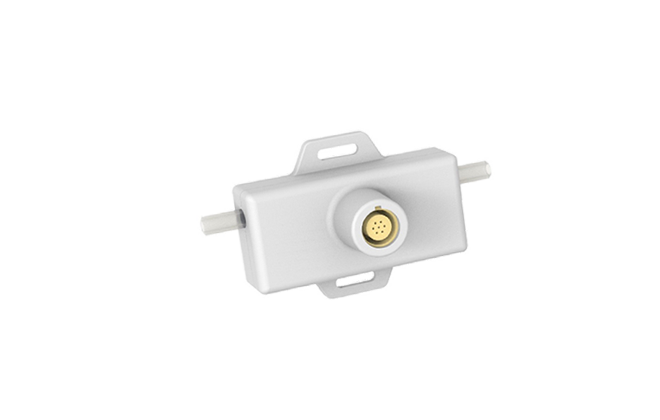

TGD series in-line ultrasonic flow sensors/flow meters are capable of measuring various manufacturing liquid media flow rates with high accuracy. The TGD series ultrasonic flow sensor/ flow meters have no moving parts, which prevents blockage even with high liquid viscosity. Supports multiple output modes for integration with equipment control systems.

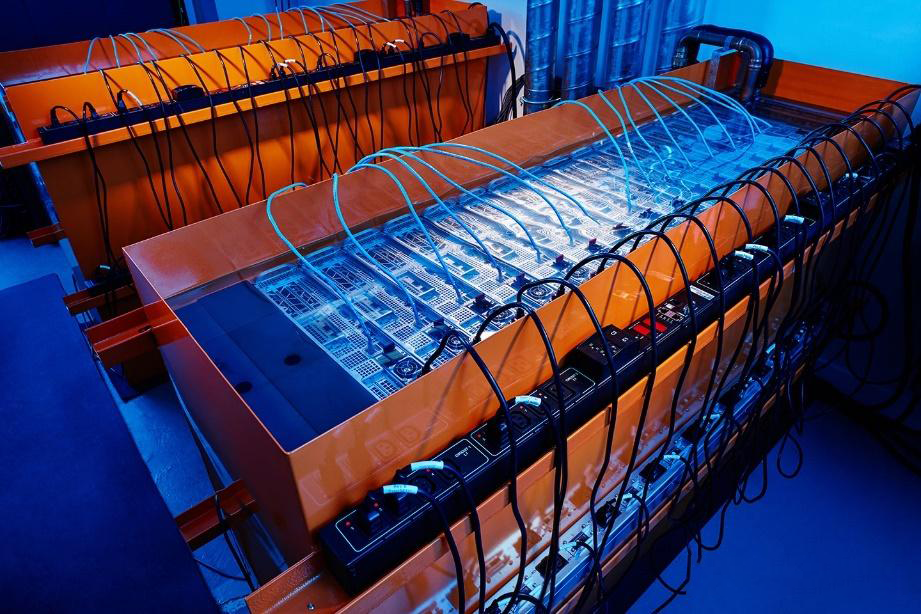

The TGD series ultrasonic flow sensor/flow meter is also suitable for measuring various coolants. Provides high-accuracy cooling water measurements to ensure accurate temperature control in cooling systems.

The TGD ultrasonic flow sensor supports measures real-time and cumulative flow data of ultra-pure water, with a display that directly shows flow rate data, allowing users to accurately monitor the flow status of water supply in the automation processes with almost no pressure loss.

The TGD ultrasonic flow meters adopt corrosion-resistant tubing materials, which are suitable for complex manufacturing working conditions.

Pre-Sale

Pre-Sale After-Sale

After-Sale